Pre painted material handling

- Material is supplied from factory to site in prime condition

- Normally all structures are primed with one coat of red oxide zinc chromate primer unless there is a specific requirement of project

- .While in transit there is a possibility of scratches on the material, which should be touched up with the same primer after unloading at site

Requirement while field painting to ensure quality:

- Primer touch-up should be done with the same type of primer as applied in plant after proper cleaning of dust, rust, etc.

- Primer/ Painting should be avoided during foggy weather conditions.

- Ensure the requirements as mentioned in Product Data Sheet (PDS) for product application and Material Safety Data Sheet (MSDS) for product safety.

- Arrange the PDS and MSDS of applicable Paint

- Spray process be used while painting at site

- Mixing of Thinner and Paint should be done as per manufacture's recommendation

- To avoid dust accumulation, material to be kept on wooden pallets or on sufficient height while painting

- After painting one side of the material leave it for sufficient time to dry, before painting the other side of the material.

- Second coat interval to be maintained as per manufacturer’s recommendation.

- Ensure final painting to be done by skilled painter

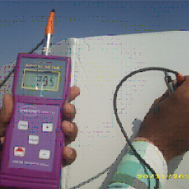

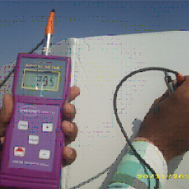

- Required Dry Film Thickness (DFT) to be maintained and measured by calibrated DFT gauge.

Safety while storage of Paint at site

- Use appropriate PPE when handling the paint containers

- Storage areas shall be kept free of weeds, debris, and other combustible material

- All storage rooms should have a proper ventilation system to provide fresh air

- Paint should be stored in sealed containers at a cool and dry place away from direct sunlight and any heating source

- Do not stack more than 3 containers

- A minimum space of 2 feet should be maintained between rows in which the containers are kept

- Empty containers shall be stored separately with their lids open

- Wiping rags, drop cloths and paint-stained clothing shall be stored in waste cans with closed lid

- Temporary electrical wiring / fittings should not to be installed in the paint storage area

- Half-filled containers or unused paints should be marked properly for traceability and should be used by the next day

Safety during Painting activity

- Before starting painting activity tool box training should be conducted and on job safety analysis to be organized

- Worker should wear proper clothes to cover full body and use hand gloves to avoid any direct contact with paint

- Wear an approved paint/spray/respirator, safety goggle while painting

- Ensure use of Personal Protective Equipment’s like safety helmet, full body safety harness/Lifeline etc. during painting at height

- Barricade/isolate the ground level and the area below the painting activity

- Keep food and drink away from areas being painted

- For any paint activity at night, proper illumination and supervision should be ensured which should be approved by an appropriate authority

- Once the painting activity is done the painter should properly wash hands, arms, face before eating/drinking and should change into clean clothing before leaving the work site

- If the worker feels unfit like dizziness while painting , he should be taken to the open area for fresh air

Safety Precautions at site for storage and painting activity

- Material Safety Data Sheet shall be displayed at the paint storage area and circulated to all supervisors and above level

- Entry to the paint area shall be restricted

- Display safety signage/warnings at the paint storage and at the painting yard

- Do not carry match boxes or cigarette lighters or any inflammable products to the site

- Smoking, Grinding, gas cutting, welding, working with naked flames, etc. are strictly prohibited at the paint storage area and during the painting activity

- Appropriate fire extinguishers/ sand buckets should be available at the storage area and at site

- Continuous supervision shall be done at the site

- Test certificate of air compressor to be handed over and ensure proper safe guarding of the moving parts of air compressor

- Provide safe access for workers and ensure a stable work platform during painting activity at height

- Safety Engineer/Safety officer should be available at site during painting activity

- Ensure all lifting equipment and gears which are used during painting at height are third party inspected and records are maintained for the same

- Always follow the manufacturer’s recommendations when cleaning spraying equipment

- The paint cleaning fluid should be disposed properly in an safe manner