| If you are having troubles viewing this e-mailer, kindly "<click here" for the online version. |

|

| |

| |

|

Director's Epistle

| |

Dear Readers,

Interarch successfully executed the first Building Innovators forum in Chandigarh, Punjab. The event started with an introductory presentation by Ishaan Suri, Director & Head Corporate Marketing. The event brought together the best minds and reputed architects of the city and the Punjab region. Interarch successfully executed the first Building Innovators forum in Chandigarh, Punjab. The event started with an introductory presentation by Ishaan Suri, Director & Head Corporate Marketing. The event brought together the best minds and reputed architects of the city and the Punjab region.

|

|

| |

We look forward to seeing you at our next event coming up in your city.

Best Regards,

Arvind Nanda & Gautam Suri

Founder Directors - Interarch Building Products

|

|

|

New Possibility - Interarch Light Building System for Hilly Areas |

| |

|

|

|

| |

Interarch Light is the perfect solution for Remote & Hilly areas where it is difficult to find labor and it is difficult to transport building construction material. Interarch Light offers the world’s most advanced end - to - end steel frame building solutions. It can be very easily used due to the following features:

Benefits of Interarch Light in Hilly Areas

- Requires minimal foundations

- Dry wall technology for exterior and interior finishes

- Light civil foundations & minimal wet construction

- Easy to transport & Fast to install

- Light weight & economical Buildings

- Strong & safe buildings

- Earthquake resistance is more than conventional buildings

- Eco- friendly and temperature resistant buildings.

- Low Maintenance

Applications of Interarch Light

- Villas

- Guest houses

- Resorts

- Cottages

- Interarch Light building allows fast and clean erection in just 45- 60days.

|

|

|

| |

|

|

|

|

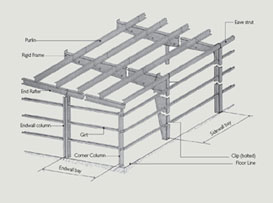

Pre-Engineered Building Components: Secondary Framing System |

| |

|

|

| |

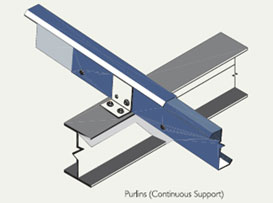

Secondary framing consists of elements which support the roof and wall sheeting and transfer load to the primary framing. It includes Roof purlins, Wall Grits, Eave Struts, and Clips etc.

Roof Purlins

- They are cold formed Z profiles and are fixed to the top flanges of the rafters by means of clips bolted to the rafters, and the purlin web bolted to the clips. Purlin ends overlap to act as continuous.

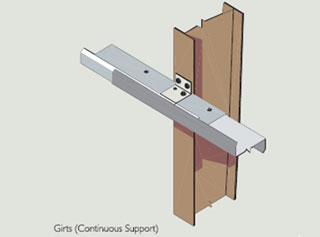

Wall Grits

These are fixed to the outer flange of the side wall columns. They have two types of fixations:

- Fixed to the outer flange of the side wall columns by means of clips bolted to the column and grit web bolted to the clips.

- End wall grits and flush grit on the side walls are normally flushed to the outer flange of the columns by means of clips which are bolted to the column web and grit web bolted to the clips.

Eave Struts

- They are C profiles or double Z profiles and are fixed to the outer flange of the side wall columns by means of clips bolted to the column and leave strut bottom flange bolted to the clip.

|

|

| |

|

|

|

| Interarch Expert opinion - Jalaj Sharma, Head Engineering at Interarch |

| |

|

|

| |

I would like to bring light to the fact that the current IS standard being followed in India are more favorable to conventional system of construction rather than for Pre-Engineered steel buildings, we have noticed the weight of the buildings designed through IS standard are always more than the one design in other International Standards like AISC & BS Codes. I would like to highlight some more facts:

As you know Pre-engineered buildings on the average are 30% lighter through the efficient use of steel. Primary framing members are tapered (varying depth) built up sections with the large depths in the areas of highest stress. Slender sections are used to achieve greater strengths and economy.

- Slender Sections are very superficially covered in IS800-2007 under Clause 3.7.2(d). Most of the matter published in IS800-2007 has been taken from BS5950-1:2000. The extract from BS5950-1:2000 covering slender sections under clause 3.6 have been suggested as addendum to existing IS800-2007.

- A section has been added for Members with one flange laterally restrained which is very important for the analysis and design of pre-engineered structures. BS5950-1:2000 has covered this in Annex G which may be introduced as a new annexure to existing IS800-2007.

- Provision of Chapter 12/IS 800:2007 for Pre-Engineered Structures

Pre-engineered structures which generally cover light structures up to 18.0 m height. These are generally with pinned bases. These are with low lumped mass as primary members are thin and slender and secondary members are made of Z sections ranging from 1.6 mm to 2.5 mm which are 30% lighter than conventional hot rolled Channels. Provisions mentioned in Chapter 12 are generally applicable for conventional Steel structure with heavy lump masses.

These provision mentions in Chapter 12 need not be applicable to pre-engineered a structure which falls under the category of low rise buildings and have light lumped masses. These structures can be buildings or buildings with single or multilevel mezzanine up to 18.0 m height. These structures need not satisfy the requirements of this section, provided they can accommodate the resulting deformation without permanent failure.

|

| |

|

|

|

| Testimonial |

| |

|

|

| |

We really appreciate the effort put in by their team at all stages, resources deployed & cooperation extended for the satisfactory and timely completion of this project. We wish them all the best for all future assignments.

This is to appreciate that M/s INTERARCH BUILDING PRODUCTS has successfully completed the work of Design, Manufacture, Supply& erection of Pre Engineered Buildings of our R&B DENIMS LTD. Surat, Gujarat. We really appreciate the effort put in by their team at all stages, resources deployed & cooperation extended for the satisfactory and timely completion of this project. We wish them all the best for all future assignments.

This is to appreciate that M/s INTERARCH BUILDING PRODUCTS has successfully completed the work of Design, Manufacture, Supply& erection of Pre Engineered Buildings of our R&B DENIMS LTD. Surat, Gujarat.

|

|

| |

|

|

|

| Trivia Question of the Month |

| |

|

|

| |

|

|

| |

Q1. Terminal 3 of the Indira Gandhi International Airport at New Delhi, 5th largest Airport Terminal in Asia delivered by Interarch in 8th Months was recently conferred the “Leadership in Energy and Environmental Design (LEED) New Construction” rating by the Indian Green Building Congress (IGBC) for green buildings. Can you tell the rating won by T3?

- Option 1: Certified

- Option 2: Silver

- Option 3: Gold

- Option 4: Platinum

First 3 CORRECT answers will get a special gift from Interarch

(To answer, please visit the Interarch page on Facebook, click Like and post your answer on the wall)

Log on to the Interarch Face Book page (click link below) and write your answers

http://www.facebook.com/interarchbuildings |

|

| |

|

|

|

|

Events at Interarch |

| |

|

|

| |

|

|

| |

Team Interarch feels proud to Share the success of its 1st Building Innovators Forum held in Chandigarh, Punjab. Building Innovators Forum is about bringing together a knowledge driven congregation of industry leaders, architects, consultants, builders, experts, and innovators of the steel buildings community of India. Team Interarch feels proud to Share the success of its 1st Building Innovators Forum held in Chandigarh, Punjab. Building Innovators Forum is about bringing together a knowledge driven congregation of industry leaders, architects, consultants, builders, experts, and innovators of the steel buildings community of India.

The reason we chose Chandigarh to launch our Building innovators forum, because we see Punjab as a potential market for pre-engineered building solutions. Also, we have undertaken some very good projects there.

Via this forum, we are not only bringing our stakeholders together but also enriching our knowledge in identifying the major growth sectors/areas and strengthening our base to better our services.

We at Interarch believe that through this forum would also be educating the target audience about the concept of Pre-Engineered Buildings and it will help us in getting involved extensively architects & consultants to deliver better results.

We will be taking the forum to other cities in due course of time. Under this forum, we plan to organize closed group interactions, seminars, and events etc. with an objective to exchange ideas amongst the participants and bring in more synergy and networks to the business.

|

|

| |

|

|

|

|

Major Projects Win

- Sharda Motors, Haryana

- Sunshine Enterprise, Gujarat

- TATA Marcopolo, Dharwad

- Ballarpur Industries Ltd, Maharashtra

- Castmet Packaging Pvt. Ltd.

Major Projects Completed

- Pithampur Tools Pvt. Ltd., Madhya Pradesh

- Marthawada Auto Cluster, Maharashtra

- VijaynathInterior & Exteriors Pvt. Ltd., Maharashtra

- Abellon Clean, Gujarat

Interarch In Press

- Daily Post, Chandigarh

- Business Standard, Chandigarh

- The Masterbuilder, June Issue

- Projects Monitor, June Issue

- B2B purchase, June Issue

- Steel Structures & Metal Buildings

|

Buildings Made Possible in Steel - The Arcelor Mittal Orbit

| |

Located in the heart of London Olympic park between the Located in the heart of London Olympic park between the

Olympic park & the Aquatics Centre is the Arcelor Mittal

Orbit an Ideal showcase for versatility of steel.

The orbit is more virile & expressive rather than graceful, yet the anthropomorphic qualities and elegant interventions make it fitting addition to the Olympic park.Steel was the only metal considered for the project as it is the only material that could provide the minimum thickness and maximum strength required for the coiling structure.

Special Features Special Features

- Height - 115 m

- Building tonnage - 2000T steel

- Spiral Staircase with 455 stairs

Facts & Figures

- Tallest sculpture in UK, 22m Taller than Statue of Liberty

- Can accommodate 5000 visitors a day

- 2000 tonnes of steel is used of which 57% is recycled

- The Orbit is steadied by a tuned mass damper

- Composed of 366 star nodes, each 4 m tall

-

Stainless steel expanded metal with a graded opacity has been used to clad the staircase and ramp, leaving the ruby red steelwork visually intact Stainless steel expanded metal with a graded opacity has been used to clad the staircase and ramp, leaving the ruby red steelwork visually intact

- The sophisticated computational design is described as a systematic, forensic, real time form

- It represents a radical advance in the architectural field of combining sculpture and structural engineering.

|

|

|

| |

|

|

INTERARCH BUILDING PRODUCTS PVT. LTD., Central Marketing Office, B-30, Sector 57, NOIDA - 201 301, INDIA

Tel.: +91-120-4170200, 2581029, Fax: +91-120-2581017, E-mail: info@interarchbuildings.com

visit us at: www.interarchbuildings.com , www.facebook.com/interarchbuildings   |

|

We really appreciate the effort put in by their team at all stages, resources deployed & cooperation extended for the satisfactory and timely completion of this project. We wish them all the best for all future assignments.

This is to appreciate that M/s INTERARCH BUILDING PRODUCTS has successfully completed the work of Design, Manufacture, Supply& erection of Pre Engineered Buildings of our R&B DENIMS LTD. Surat, Gujarat.

We really appreciate the effort put in by their team at all stages, resources deployed & cooperation extended for the satisfactory and timely completion of this project. We wish them all the best for all future assignments.

This is to appreciate that M/s INTERARCH BUILDING PRODUCTS has successfully completed the work of Design, Manufacture, Supply& erection of Pre Engineered Buildings of our R&B DENIMS LTD. Surat, Gujarat.

Team Interarch feels proud to Share the success of its 1st Building Innovators Forum held in Chandigarh, Punjab. Building Innovators Forum is about bringing together a knowledge driven congregation of industry leaders, architects, consultants, builders, experts, and innovators of the steel buildings community of India.

Team Interarch feels proud to Share the success of its 1st Building Innovators Forum held in Chandigarh, Punjab. Building Innovators Forum is about bringing together a knowledge driven congregation of industry leaders, architects, consultants, builders, experts, and innovators of the steel buildings community of India.

Interarch successfully executed the first Building Innovators forum in Chandigarh, Punjab. The event started with an introductory presentation by Ishaan Suri, Director & Head Corporate Marketing. The event brought together the best minds and reputed architects of the city and the Punjab region.

Interarch successfully executed the first Building Innovators forum in Chandigarh, Punjab. The event started with an introductory presentation by Ishaan Suri, Director & Head Corporate Marketing. The event brought together the best minds and reputed architects of the city and the Punjab region.

Located in the heart of London Olympic park between the

Located in the heart of London Olympic park between the

Stainless steel expanded metal with a graded opacity has been used to clad the staircase and ramp, leaving the ruby red steelwork visually intact

Stainless steel expanded metal with a graded opacity has been used to clad the staircase and ramp, leaving the ruby red steelwork visually intact