| If you are having troubles viewing this e-mailer, kindly "click here" for the online version. |

|

| |

| |

|

Director's Epistle

| |

Dear Readers,

| Interarch is proud to launch Building Innovators Knowledge Speak for the Interarch Building Innovators community. Knowledge speak will cover and feature regular updates on Steel & Metal Building Industry, construction updates, technical updates on technology, and will also release a tabloids though regular online & print communication by dignified speakers of the industry. |

|

|

|

| |

It will give an opportunity to all Building Innovators members to share their expertise and experience with the complete architectural and industrial fraternity on various topics related to steel construction and metal building design.

We will be releasing detailed information document of the same through separate communication that will reach you shortly along with honorary membership form to join Interarch Building Innovators

Best Regards,

Arvind Nanda & Gautam Suri

Founder Directors - Interarch Building Products

|

|

|

|

| Interarch Contribution to the Environment: Siting and Structure Design & Efficiency |

| |

|

|

| |

The foundation of any construction project is rooted in the concept and design stages. The concept stage, in fact, is one of the major steps in a project life cycle, as it has the largest impact on cost and performance.In designing environmentally optimal buildings, the objective is to minimize the total environmental impact associated with all life-cycle stages of the building project. However, building as a process is not as streamlined as an industrial process, and varies from one building to the other, never repeating itself identically. In addition, buildings are much more complex products, composed of a multitude of materials and components each constituting various design variables to be decided at the design stage. A variation of every design variable may affect the environment during all the building's relevant life-cycle stages

|

|

|

|

Engineered Roof Systems v/s GI Roof Engineered Roof Systems v/s GI Roof |

| |

|

|

| |

| Tracdek Engineered Roofing |

G.I Roofing |

| Tracdek roofing system is designed, engineered and customized system made to suit the requirement of the client |

G.I roofing are not customized and engineered roof system and is available in standard length panels and is manually cut and installed at site as per site conditioned |

| Maximum single sheet length is 12 meters for screw down Tracdek Hi-Rib systems and limitless length for standing seam SS-2000 systems |

Maximum single sheet length 3 meter |

| 100% water tight sheeting system as the sheet has well deigned side laps and fasteners that do not allow water seepage |

Leakage due to poor side lap design and non standard fasteners |

| Aesthetically better and can be ordered to any colour specification |

Standard colours and non-compatible colour coding |

| Heat transfer is less as Bare Galvalume reflects light better and due to its alloy coating, absorbs less heat |

Heat transfer is high as it is an untreated GI surface |

| Has the capacity to withstand high loads depending on the grade of material used |

Cannot withstand high loads as the grade of the sheet cannot always be determined |

| 1st maintenance min after 20 years, Non corrosive |

Corrosion ratio depends on the grade of material |

| Roll formed profile systems with various profile available |

Press made |

| Tensile strength of 550MPa |

Tensile strength is poor |

| Cut edges are covered with Galvalume alloy coating which protect sheet from corrosion |

Cut edges in the GI sheet are opened and prone to corrosion very fast |

| After sale services are taken care of due to Organized sector |

No guarantee of after sale service by shop keepers |

|

|

| |

|

| |

|

|

|

|

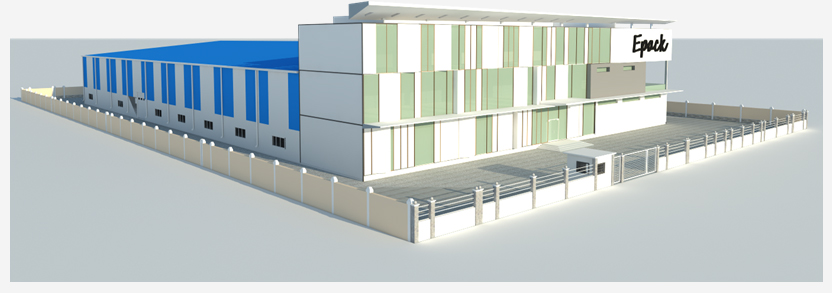

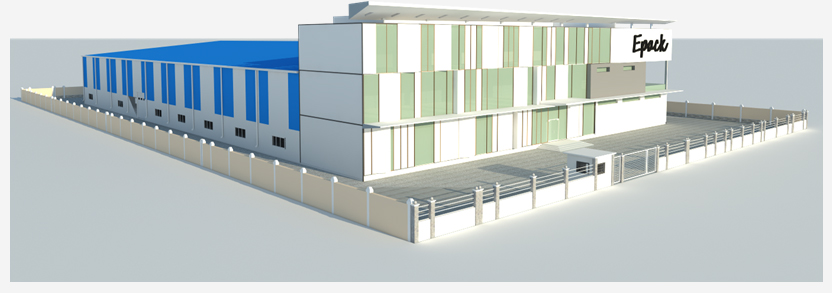

| Project Spotlight: EPACK Polymers Pvt. Ltd., Greater Noida |

| |

|

|

| |

| Project Name |

EPACK Polymers Pvt. Ltd |

EPACK Polymers Pvt. Ltd |

| Building Usage |

Manufacturing Facility |

Office Building |

| Length |

75.25 M |

53.45 M |

| Width |

53.45 M |

10 M |

| Height |

8 M Clear |

10.85 M |

| Project Area |

4022 Sq. M |

535 Sq. M |

| Special Features |

EOT Crane of 7 Tone Capacity with 5.5 M bracket height

High standards safety procedures were followed for the buildings |

Ground+2 Building

High standards safety procedures were followed for the buildings

1st Floor : 3.75 M Height

2nd Floor : 3.75 M Height

3rd Floor : 3.35 M Height |

|

|

|

|

| Customer Testimonial |

| |

|

|

| |

We appreciate the efforts, resources deployed and cooperation extended put in by the team of Interarch Building Products Pvt. Ltd. at all stages, for the satisfactory and timely completion of this project. We wish them success for all their future assignments. We appreciate the efforts, resources deployed and cooperation extended put in by the team of Interarch Building Products Pvt. Ltd. at all stages, for the satisfactory and timely completion of this project. We wish them success for all their future assignments.

|

|

| |

|

|

|

|

New Project Wins

- Utkal Alumina International Ltd,Orissa

- The Bombay Dyeing & Mfg. Co. Ltd, Maharashtra

- Severn Glocon India Pvt Ltd in, Tamil Nadu

- Orient Craft Ltd , Hyderabad

Projects Completed

- Jaguar Land Rover Service Center, AMP Motors Pvt.

Ltd, Gurgaon

- N S Ventures, Mandideep

- Centurion University of Technology and Management, Bhubaneswar

- Tata Motors Ltd, Pune

- Trans India Nonwovens Pvt. Ltd, Jaipur

Press Coverage

- B2B Purchase

- Civil Engineering & Construction Review

|

Industry Spokesperson: Ar. Prabhat Bhargava, Gwalior

| |

Bhargava Building Atelier (P) Ltd. is a renowned architect firm established by Architect Prabhat Kr. Bhargava in Gwalior. He is civil engineer having vast experience of 30 years in engineering & consulting services. He had done M.Tech from Roorkee University. Bhargava Building Atelier (P) Ltd. is a renowned architect firm established by Architect Prabhat Kr. Bhargava in Gwalior. He is civil engineer having vast experience of 30 years in engineering & consulting services. He had done M.Tech from Roorkee University.

Bhargava Building Atelier Pvt. Ltd. has completed large number of projects. Which includes Industrial, Residential, commercial, urban designing and landscaping, Building material & Soil Testing, and Surveys etc. One of his favorite projects is Captain Roop Singh Cricket Stadium at Gwalior.

According to him, role of an architect is changing day by day towards modular design. To ensure stability Indian building system needs to work on different Climatic conditions. His top three Pre-Engineered works are manufacturing unit of Tripti Alcobrew Ltd., Krishna Electrical Pvt. Ltd. & Agro Solvent Products Pvt. Ltd. For longer building life and maintenance he suggests cracks& deflection should be checked immediately as and when they arise. According to him, role of an architect is changing day by day towards modular design. To ensure stability Indian building system needs to work on different Climatic conditions. His top three Pre-Engineered works are manufacturing unit of Tripti Alcobrew Ltd., Krishna Electrical Pvt. Ltd. & Agro Solvent Products Pvt. Ltd. For longer building life and maintenance he suggests cracks& deflection should be checked immediately as and when they arise.

Nuts & bolts must be checked after every 2 years, maintenance of drainage systems is also very necessary.

He stated that at present 60% of the constructions is on the pattern of Pre-Engineered Buildings in M.P. region and Food and Textile Industries are two hot industries where scopes of Pre-Engineered Building construction are large & diversified.

|

|

|

|

|

|

Events at Interarch |

| |

|

|

| |

|

Building Innovators Close Group Seminar

Another milestone added to the Interarch Building Innovators Close Group Seminar- Pantnagar, Uttrakhand

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

Diwali Festival Celebrations & Rangoli Competition at H/O Noida |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

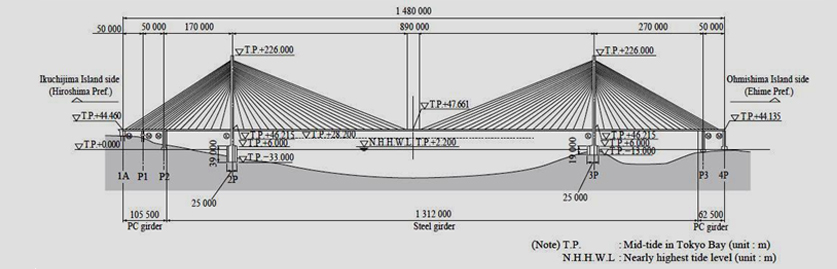

Building Made Possible in Steel: Tatara Bridge, Japan

|

| |

|

|

| |

|

|

| |

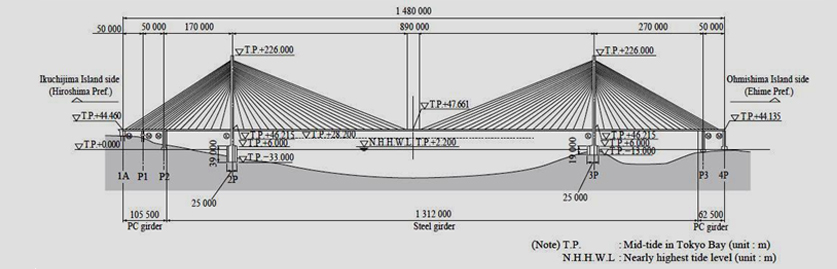

- It is located at the center of the Honshu - Shikoku Bridge on Nishiseto Expressway.

- One of the world’s longest cable - stayed bridge

- Total Steel Weight: 30,000 Tons

- Length of 1480 m

- Width of 30.6 m

- Max Cable Length - 460 m

- Length is divided in 3 spans of 270m, 890 m in the center span & 320m.

- The TATARA Bridge is the 2nd longest cable-stayed bridge in the world.

- Construction of the bridge took a little more than six years and was accomplished without any accidents

- A 3D wind tunnel test was carried out during the design stage to verify its wind-resistance stability.

- The towers are inverted Y-shaped steel structures, with slits in an upper tower for aesthetics, as well enhanced aerodynamics.

- The suspended girders are primarily stream-lined steel box girders, but pre-stressed concrete girders make up the end spans supported by the intermediate pier to act as a counter-balance to the weight of the main span.

- It has a 2 bay road running on both sides of which one is called a sidewalk for motorized bicycles & Pedestrians

- Cables Installed in 21 levels were Two - plane multi - fan Cables

|

| |

|

|

| |

|

|

|

INTERARCH BUILDING PRODUCTS PVT. LTD., Central Marketing Office, B-30, Sector 57, NOIDA - 201 301, INDIA

Tel.: +91-120-4170200, 2581029, Fax: +91-120-2581017, E-mail: info@interarchbuildings.com

visit us at: www.interarchbuildings.com, www.facebook.com/interarchbuildings   |

|

Engineered Roof Systems v/s GI Roof

Engineered Roof Systems v/s GI Roof We appreciate the efforts, resources deployed and cooperation extended put in by the team of Interarch Building Products Pvt. Ltd. at all stages, for the satisfactory and timely completion of this project. We wish them success for all their future assignments.

We appreciate the efforts, resources deployed and cooperation extended put in by the team of Interarch Building Products Pvt. Ltd. at all stages, for the satisfactory and timely completion of this project. We wish them success for all their future assignments.

Interarch engineered, manufactured & delivered the first Pre- Engineered Steel Multi storey office complex in India

Interarch engineered, manufactured & delivered the first Pre- Engineered Steel Multi storey office complex in India

Bhargava Building Atelier (P) Ltd. is a renowned architect firm established by Architect Prabhat Kr. Bhargava in Gwalior. He is civil engineer having vast experience of 30 years in engineering & consulting services. He had done M.Tech from Roorkee University.

Bhargava Building Atelier (P) Ltd. is a renowned architect firm established by Architect Prabhat Kr. Bhargava in Gwalior. He is civil engineer having vast experience of 30 years in engineering & consulting services. He had done M.Tech from Roorkee University.  According to him, role of an architect is changing day by day towards modular design. To ensure stability Indian building system needs to work on different Climatic conditions. His top three Pre-Engineered works are manufacturing unit of Tripti Alcobrew Ltd., Krishna Electrical Pvt. Ltd. & Agro Solvent Products Pvt. Ltd. For longer building life and maintenance he suggests cracks& deflection should be checked immediately as and when they arise.

According to him, role of an architect is changing day by day towards modular design. To ensure stability Indian building system needs to work on different Climatic conditions. His top three Pre-Engineered works are manufacturing unit of Tripti Alcobrew Ltd., Krishna Electrical Pvt. Ltd. & Agro Solvent Products Pvt. Ltd. For longer building life and maintenance he suggests cracks& deflection should be checked immediately as and when they arise.