|

| |

|

| |

|

It brings us pleasure to announce that our newsletter has completed 3 years and reached a readership of more than 35,000 across India; with this issue- we are launching Volume 4 of the newsletter.

We would like to thank our readers and all our partners for contributing to the newsletter in form of informative articles and interviews for successful completion of three years of this journey

We hope the newsletter has been a regular source of information to you and we will try to keep you updated with all latest trends and new technologies in this sector.

|

| We would also like to share the launch of Interarch Infra Facebook page and its website www.interarchinfra.com. & a new section "Ask an Expert" Please join us at Facebook to know more about Interarch Infrastructure. |

| |

|

Thanks & Regards,

Arvind Nanda & Gautam Suri

Founder Directors - Interarch Building Products |

|

|

| |

| |

| Healthcare sector in India |

| |

|

| Indian government expenditure on health care is the highest amongst all the developing countries. The expenses of the healthcare industry comprise 5.25% of the GDP. There are even chances that the health care market could experience a hike and attain a figure ranging $53 to $73 billion. The Indian Health Care Industry earns revenues accounting for 5.2% of gross domestic product.

Indian healthcare industry comprises of hospitals and allied sectors which is projected to grow 23% per annum to touch US$ 77 billion by 2012 and according to the current estimated size of US$ 35 billion. The Industry has registered a growth of 9.3 % between 2000-2009, as compared to the sector growth rate of emerging economies such as China, Brazil and Mexico. There would be increase in number of public and private healthcare facilities which are expected to propel demand for the industry, accounting for another US$ 6.7 billion.

Majorly the Indian Health Care Industry and Fortis Hospitals plans to invest US$ 53.7 million and plans to expand the facilities for the pan-India.Columbia Asia Group, which already has six hospitals in the country- Asia's leading hospital chain, plans to ramp-up its operations in India by opening eight more multi-specialty community hospitals with a total capacity of 800 beds by the year of mid-2012. Total investment of US$ 177.1 million for 14 hospitals is projected. |

|

| In Hyderabad, the NarayanaHrudayalaya has inaugurated the phase-I of the 5,000-bed health city which is the Hub for the multinational corporations. The company plans to expand its presence to seven more cities to take the total number of hospitals to 14 in the next 2-3 years.

Cochlear Ltd plans an Australian medical devices company to set up its wholly-owned subsidiary in India, to provide better patient and product support. In next five years the Company also plans to invest about US$ 15 million. |

|

| |

|

| |

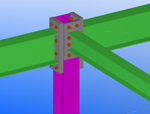

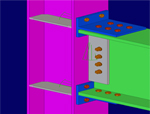

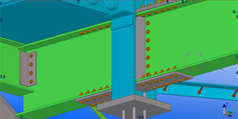

| Connection Details in Structural Steel |

| |

|

By Mr. Vishal Khandelwal, DGM Design Interarch Infrastructure & Mr. Neeraj Lohani, A.M. Design

The common connection used in steel structures can be broadly classified into the following categories:

Shear Connections

A connection which is only capable of transferring shear from one connected part to another, but no moment is transferred, it is known as Shear connection or Pin connection. Since, the shear is practically borne completely by the web of a beam and the tension compression couple created by moment is mainly borne by the top & bottom flanges of the beam, in shear connection only webs are connected and the flanges remain unconnected. A shear connection is only provided at the zero bending moment locations of a beam, which is typically the end support location of a simply supported beam (e.g. floor joists). by the top & bottom flanges of the beam, in shear connection only webs are connected and the flanges remain unconnected. A shear connection is only provided at the zero bending moment locations of a beam, which is typically the end support location of a simply supported beam (e.g. floor joists).

Common shear connections in use are

a. Double clip connection

b. Fin plate connection

c. End plate connection

Moment Connections Moment Connections

A connection which is in addition to the shear connection above is capable of transferring the flange tension and compression forces (due to tension, compression generated by bending moment at the connection location) is referred as a moment connection.

The common forms of moment connections in use are

a. Extended end plate moment connection a. Extended end plate moment connection

b. Flush end plate moment connection

c. Spliced moment connection

d. Seated moment connection |

|

| |

| Fire Proofing in Structural Steel |

| |

|

The structural elements of a building need to be designed to withstand the effects of building compartment fires, so as to minimize the likelihood of structural collapse. The use of steel framed construction and in particular the use of fireproofing materials is known to provide fire resistance levels for the steel elements of buildings.Fireproofing is achieved by applying fireproofing covering materials to thermally protect the underlying steel from the heat of the fire. The type and amount of fire proofing material is dependent on a number of variables, some of which include

| |

|

Size of steel members in question |

|

Fire severity |

|

Fire rating or duration of exposure to a given fire |

|

Time of application of the fireproofing covering |

|

Budget |

|

Aesthetics |

|

Location of project |

Conventional spray applied materials

These are the oldest and at present the most widely used form of fireproofing material. These are relatively low density materials, (at least when compared to concrete) which typically are supplied in bags, and which are mixed with water and sprayed as a type of slurry onto or around the contour of the steel profiles.

The thicker the applied material, the higher the fire rating, within maximum thicknesses which prove the material's adhesiveness to the steel during fire testing

Board Materials

Board materials, like conventional spray applied materials, have been used for a long time. Manufactured board materials are cut to size and fixed around steel sections, in essence "boxing" them in to provide the necessary fireproofing. Fireproofing boards must be able to limit the amount of cracking or spalling so as to limit the spread of hot gases to the underlying steel structure Board materials, like conventional spray applied materials, have been used for a long time. Manufactured board materials are cut to size and fixed around steel sections, in essence "boxing" them in to provide the necessary fireproofing. Fireproofing boards must be able to limit the amount of cracking or spalling so as to limit the spread of hot gases to the underlying steel structure

Intumescent Materials

Intumescent materials are those which expand to many times their original volume when heat is applied to them. They are widely used in the Passive Fire Protection or Fire Stopping market. Examples of such materials include intumescent fire collars for protection of plastic pipes or Intumescent sealant for around steel pipes. Intumescent paints can be applied at relatively low thicknesses when compared to conventional spray applied materials, and when they are subjected to the heat of a fire, expand or swell to form a thick insulating char around the steel members.

|

|

| |

| Customer Testimonial- Young Builder Program at K.R Mangalam Institute, Delhi |

| |

|

| Thanks and congratulations to your team for an interactive session on pre-Engineered steel buildings. Hope this will help our students to think in a different direction of construction. We shall be in touch and also try to arrange a plant visit to Pantnagar to take the maximum benefit of it.

|

|

| |

|

|

| Industry Spokesperson – Ankur Engineers |

| |

|

Ankur Engineers a professional engineering consultancy firm based at Indore which provides Civil & Structural Engineering services for Industrial, Commercial & Residential projects. Ar. C.S. Alekar& Ar. R.K. Gupta are the promoters of the firm. They have a vast experience and expertise in Manufacturing Industry, Food Processing Industry, Engineering Industry, Warehouse Industry, Textile Industry, Commercial Building, IT Industry & Residential buildings. Ankur Engineers a professional engineering consultancy firm based at Indore which provides Civil & Structural Engineering services for Industrial, Commercial & Residential projects. Ar. C.S. Alekar& Ar. R.K. Gupta are the promoters of the firm. They have a vast experience and expertise in Manufacturing Industry, Food Processing Industry, Engineering Industry, Warehouse Industry, Textile Industry, Commercial Building, IT Industry & Residential buildings.

According to them, Multi Storey Buildings for industrial and commercial purposes both are upcoming in India and solvent industry is the upcoming industry in MP region.

Recently new design implemented by them was to club the RCC Building with Pre-Engineered Building with 2 beam support to avoid hurdle with the conveyor. Their most favorite project is Metalman Auto Pvt. Ltd, Aurangabad which involves 2 parallel gantries to match the utility of the manufacturing process.

With their experience with various Pre-Engineered Building companies they shared that Interarch, with its high quality in building material and project execution makes them one of the leaders in this segment in the Madhya Pradesh region. |

|

| |

| Building Maintenance Tip: Maintenance of Doors |

| |

|

Lubricate hinges and lockset |

|

|

Remove dirt & grit from the threshold |

|

Ensure that the door should not swing back and strike the wall panels, as this will sprain the hinges and will damage the panel |

|

|

| |

| |

| New Project Wins |

| |

|

Indospace Logistics Pvt. Ltd, Tamil Nadu |

|

|

Central India Logistics, Maharashtra |

|

Western Refrigeration, Gujarat |

|

SMS India Pvt. Ltd, Orissa |

|

Dee Development Engineers Pvt. Ltd, Haryana |

|

| |

| Projects Completed |

| |

|

Skoda Auto India Pvt. Ltd, Maharashtra |

|

|

Hindustan Aqua Limited, Orissa |

|

Dainik Bhaskar Corporation Ltd, Rajasthan |

|

Insecticides India Ltd, Gujarat |

|

Osaw Agro Industries Ltd, Punjab |

|

| |

| Press Coverage |

| |

|

Ace Update |

|

|

CE & CR |

|

Construction Week |

|

Construction World |

|

MGS Architecture |

|

NBM & CW |

|

Steel Structures & Metal

Buildings |

|

The Masterbuilder |

|

B2B Purchase |

| |

|

|

|

| |

|

|

| |

|

| |

| CSR at Interarch: Fire Safety Week Celebration at Plant |

| |

|

Fire Safety Training for all Interarch's Pantnagar plant employees was arranged with collaboration of Fire Department Rudrapur. Fire Safety Training for all Interarch's Pantnagar plant employees was arranged with collaboration of Fire Department Rudrapur.

This initiative was to coincide with The Fire Safety Week Celebrations by Fire Department, USN. |

|

| |

| |

| Trivia Question of the month |

| |

| Q. Which building delivered by Interarch has received the Platinum rating by IGBC |

|

| a) |

DIAL Terminal 3, New Delhi |

| b) |

Bayer Life sciences, Greater Noida |

| c)> |

Tata Motors, Dharwad |

| >d) |

Asian Paints, Pune |

|

| |

| Please post your answers on Facebook. |

| |

| Ask an Expert |

| |

| We want to offer all our readers a platform to ask us questions or technical query regarding pre-engineered buildings engineering, Production or Site Management during erection

We will be happy to provide you with answers, case study and real time knowledge through site and plant visits to educate you properly.

Please visit us on Facebook and post your queries there. |

|

| |

|

|

|

|

|

|

|

Click here to submit your enquiry online |

|

| INTERARCH BUILDING PRODUCTS PVT. LTD.

Central Marketing Office, B-30, Sector 57, Noida - 201 301, India

Tel.: +91-120-4170200, 2581029 | Fax: +91-120-2581017 | E-mail: info@interarchbuildings.com |

visit us at: www.interarchbuildings.com, www.interarchinfra.com |

|

|