|

|

| |

|

Dear Readers,

We are happy to share with you that the best Indian companies and MNC companies bank on Interarch for pre-Engineered Buildings requirement in India. We are satisfied with the business generated and the current growth rate achieved by the company. This year too, in 65 days we have won orders for over 250 Crore from Parle Agro Pvt Ltd, Greenply Industries Ltd, Asian Paints Ltd , Tata Motors Ltd , Safex Logistics Solutions Pvt Ltd, ITC Limited, Ashirwad Pipe ltd etc. and many more.

Pre-Engineered steel construction market has been growing in double figure year-on-year since the last few years, It would certainly not be an exaggeration to say that industry is catching-up very rapidly. In fact, pre-engineered building sector has started getting its due credit as a favorable alternative construction methodology in India today. We feel GST is going to be a game changer and we are foreseeing huge demand, particularly in the warehousing sector, once GST is implemented in India.

Thanks & Regards,

Arvind Nanda & Gautam Suri |

|

|

|

| Interarch Light Building Application: Residential Building |

|

| |

|

| Interarch Light Gauge Building Systems is ultimate union of design, materials, machinery and manufacturing, of standard stud and track profiles. It is ideal for situations where speed, reliability and flexibility are critical in developing a project. |

|

| |

|

| |

|

|

|

| Project Management Tip: Best Practices followed at site to keep the environment clean |

|

| |

|

|

Ensuring that emission controls are effective for vehicles, machinery and motors are well maintained |

|

Turning off of the vehicles and machinery engines when not in use |

|

Store liquids like paints diesel etc away from drains and water courses |

|

Ensuring taps and hoses properly closed when not in use, unnecessary wastage should be avoided |

|

The wooden battens are recollected at the site so that they can be reused |

|

The Insulation material should be sent to approved Treatment, Storage and Disposal facilities |

|

Water-based paints are more environment friendly than solvent-based alternatives, so wherever possible it should be used |

|

Painting area should be covered from sides and polythene sheets should be layed to prevent seepage of paint to soil and the waste is sent to approved Treatment, Storage and Disposal facilities |

|

|

|

|

|

|

| Project Spotlight: Maxxis Rubber India Pvt Ltd |

|

| |

|

| Interarch in process of delivering the largest tyre manufacturing plant in Gujarat for Maxxis Rubber India Pvt Ltd at Sanand in Gujarat. The scope of work covers the design & engineering fabrication, supply and erection of the Pre- Engineered steel building. The building will be used for material warehouse, Mixing Room, Calendaring Room, Mixing room for inner tube and extrusion. |

|

| |

|

| |

| Project Name |

Maxxis India Pvt Ltd |

| Project Location |

Sanand, Gujarat |

| Total Area |

107150 Sq.M |

| Building Usage |

Greenfield Tyre Manufacturing Facility |

| Length |

426.70 M |

| Breath |

91.80 M |

| Height |

28.83 M |

| Design Code |

MBMA-2006 |

| Seismic Zone |

III |

| Roof Slope |

1:20 |

|

| |

|

|

|

|

|

|

| Industry Spokes Person: Mr.Hiten J Shah-S3M Design Consultant |

|

| |

|

S3M Design Consultants LLP is a professional Consultancy firm providing complete services such as Civil, Structural, Architectural, Public Health Engineering, Mechanical, Electrical and Piping, Procurement Assistance and Project Management Consultancy necessary for timely and satisfactory completion of any project. The founding Partners have a cumulative professional experience of more than 80 years. Mr. Hiten J Shah holds Managing Partner role have a total experience of 32 years for large Projects of varied nature with complex utilities & time bound completion. He has done M.E. (Structures) in 1985 from M.S. University, Baroda

As per Mr Shah in European countries, a steel building is generally designed for flat roof system and maximum projects are designed and engineered keeping pre-engineered steel in mind, in India as currently only industry and warehouse sheds have high penetration. In years to come we will see commercial, residential and institutional buildings in steel in India. The role of architects will change in India and in next 5-10 years more applications like Multi-storey Buildings, Bridges, Hospital buildings & Farmhouses will be built using structural steel system. As per Mr Shah in European countries, a steel building is generally designed for flat roof system and maximum projects are designed and engineered keeping pre-engineered steel in mind, in India as currently only industry and warehouse sheds have high penetration. In years to come we will see commercial, residential and institutional buildings in steel in India. The role of architects will change in India and in next 5-10 years more applications like Multi-storey Buildings, Bridges, Hospital buildings & Farmhouses will be built using structural steel system.

The architects will work to optimize the loads, and make cost and time efficient structure. He suggests, before the order finalization client need to identify utilities & technical detailing of the building as it will help them to understand capable company to finalize the order. Mr Shah Feel’s Green buildings are energy efficient & eco-friendly and very useful in the long run. People should focus on designing their buildings and listing specifications which are listed by Indian Green Building Council. He also wants to advices all the Pre-Engineered Building users to clean gutters on a specific period of time during the monsoon to enjoy maintenance free buildings for longer time

We have got a very pleasant experience with Interarch in terms of quality material and timely execution at of projects and we wish them all the best for the future.

|

|

| |

|

|

| Customer Testimony |

|

| |

|

|

Interarch Building Products executed Pre-Engineered Building project of Ashirvad Pipes Ltd at Bangalore. We are satisfied with the work & happy with the timely completion of the project. Interarch Building Products executed Pre-Engineered Building project of Ashirvad Pipes Ltd at Bangalore. We are satisfied with the work & happy with the timely completion of the project.

We wish Interarch very best in all their future endeavors. |

|

|

|

| |

|

|

| Award & Recognition: |

|

| |

|

| Interarch Building Product has won award from Gamesa Renewable Pvt Ltd for Zero accident & timely completion of the project |

|

|

|

| |

| Project Won |

Project Completed |

|

|

|

|

|

|

|

ITC Ltd in Telangana |

|

Ashirvad Pipes Pvt Ltd in Rajasthan |

|

Indospace Logistics Parks Ltd. in Maharashtra |

|

Atlas Copco (India) Ltd in Maharashtra |

|

International Hospital Ltd in Karnataka |

|

|

|

|

|

|

|

Ultratech Cement Ltd in Rajasthan |

|

EFD Induction Pvt Ltd in Bangalore |

|

Kool Solutions India in Maharashtra |

|

Godrej & Boyce Manufacturing Co in Maharashtra |

|

Megaa Moda Pvt Ltd in West Bengal |

|

|

|

|

|

| |

|

|

| Training & Development at Interarch |

|

| |

|

| Interarch organized induction training for new joinee UMS team on 3 & 4 January 2017 in Pantnagar Plant. The training covered the Induction and all general topics. |

|

|

|

| |

|

|

| Press Coverage |

|

| |

|

| Interarch received Press Coverage in MGS Architecture Magazine from Page no. 18-19. |

|

|

|

| |

|

|

| Upcoming Event in Interarch |

|

| |

|

Interarch is participating in Roof India Exhibition, Mumbai from 20-22nd April 2017 |

|

|

|

| |

|

|

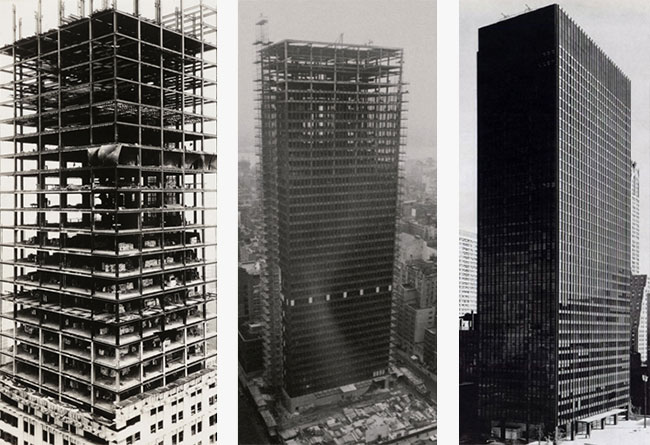

| Building made possible in Steel- The Seagram Building |

|

| |

|

The Seagram Building, like virtually all large buildings of the time, was built of a steel frame, from which non-structural glass walls were hung. As American building codes required that all structural steel be covered in a fireproof material, usually concrete, because improperly protected steel columns or beams may soften and fail in confined fires. Concrete hid the structure of the building something the architect wanted to avoid at all costs, so the architect used non-structural bronze-toned I-beams to suggest structure instead. These are visible from the outside of the building, and run vertically, like mullions, surrounding the large glass windows. This method of construction using an interior reinforced concrete shell to support a larger non-structural edifice has since become commonplace. As designed, the building used 1,500 tons of bronze in its construction

Structure of the Building:

The 38-story structure combines a steel moment frame and a steel and reinforced concrete core for lateral stiffness. The concrete core shear walls extend up to the 17th floor, and diagonal core bracing (shear trusses) extends to the 29th floor. According to Severud Associates, the structural engineering consultants, it was the first tall building to use high strength bolted connections, the first tall building to combine a braced frame with a moment frame, one of the first tall buildings to use a vertical truss bracing system and the first tall building to employ a composite steel and concrete lateral frame.

|

|

|

|

| |

|

|

|