|

|

| |

|

| |

|

|

| Best Companies in India Bank on Interarch Pre-Engineered Buildings |

|

| |

|

We are happy to Announce than Interarch has won order for over 160 Crores in January 2016 |

|

|

|

| |

|

|

|

|

| Upcoming Smart Cities in India: |

|

| |

|

The government of Indian announced the list of first 20 smart cities. An investment of Rs 50,802 crores has been proposed in selected smart cities and towns during the five-year period. This list was finalized from a list of 97 cities from state governments. The selected cities will be equipped with basic infrastructure, efficient urban mobility and public transport, IT connectivity and e-governance mechanisms.

Following is the list of 20 smart cities:

| 1. |

Bhubaneswar |

2. |

Pune |

| 3. |

Jaipur |

4. |

Surat |

| 5. |

Kochi |

6. |

Ahmedabad |

| 7. |

Jabalpur |

8. |

Vishakapatnam |

| 9. |

Sholapur |

10. |

Davangere |

| 11. |

Indore |

12. |

New Delhi (municipal council area) |

| 13. |

Coimbatore |

14. |

Kakinada |

| 15. |

Belagavi |

16. |

Udaipur |

| 17. |

Guwahati |

18. |

Chennai |

| 19. |

Ludhiana |

20. |

Bhopal |

|

|

|

| |

|

|

| Project Management Tip: Proper Way of loading & Un-loading |

|

| |

|

Crane & Sling/ Clamping Jaws/ Nylon strap etc. should be of sufficient capacity to lift the required load/material |

|

Match the material in trailer with the packing list before unloading |

|

Size specification should not be removed from crates / packet and bundles |

|

Nylon Strap to be used for unloading the sheeting material / crates etc. |

|

Structure material should be unloaded by using sling with rubber packing on the edges |

|

Long length items more than 8 meters in length should be unloaded with the help of spreader beam |

|

Tag/Guy rope to be used at the end of both members for avoiding free movement |

|

Ground should be leveled and compact for storage |

|

Wooden Pallets should be placed at equal distance to avoid distortion of material |

|

After lifting the first member/ bundle in proper manner, lift second bundle and place it over the first pallet member/bundle. All wooden pallets should be in one line and equidistant i.e1.5 to 2.0 meters |

|

All galvanized material, hardware and critical bought out items such as insulation, weld mesh, hardware etc. should be stored in covered area or with water proof tarpaulin |

|

All Bundles items i.e. Purlins, Rack/ Eave Angle, Sheets etc. should be kept at height and slope of 5° |

|

Do not stack more than four sheeting bundles on top of each other |

|

Stack the total material in such a way that it should be easily traceable & moveable to erection area at the time of erection |

|

|

|

| |

|

|

| Project Spotlight : Sai Warehousing |

|

| |

|

|

| |

| Interarch completed 2 warehouse buildings for SAI Warehousing in Gujarat. The scope of work covers the design, engineering, fabrication, supply and erection of the Pre-Engineering steel building in strict compliance with the standard and specifications. |

| |

| Key Project Highlight |

| |

| Project Name |

Sai Warehousing & Infrastructure |

| Project Location |

Chandogar, Ahmedabad |

| Project Usage |

Warehouse |

| Project Area |

9168.7635 Sqm |

| Width |

41.61 M |

| Length |

220.35 M |

| Height |

7.3 M clear height under the knee |

| Wall Cladding |

0.50mm 26 Ga. SMP Color coated Tracdek Galvalume steel sheets of 550 Mpa |

| Roofing Supplied |

0.47mm 26 Ga. Trackdel Hi-Rib Bare Galvalume steel sheets of 550 Mpa |

| Roof Slope |

1:10 |

| Special Features |

|

All Primary & secondary members (except purlins & girts) shall be applied with one coat of red oxide primer and finished with two coats of synthetic enamel paint, applied at site |

|

Purlins & Girts will be Pre-Galvanised 275 GSM |

|

Anchor bolts and templates (templates are Interarch’s property and to be returned after use) |

|

2mm thick Polycarbonate daylight panels on roof |

|

3m projection Canopy return down-take system |

|

600m Dia turbo vents with FRP base |

|

4mm bubble insulation (Aerolam Make) |

|

|

| |

|

|

| |

|

|

| Industry Spokesperson: Mr. Anil Hinge, Director, Rass Project Consultants Pvt. Ltd., Pune |

|

| |

|

According to Mr. Hinge, Pre-Engineered buildings designed & engineered with American & European Standards and codes consumes less steel than the designs done as per Indian Standards. According to Mr. Hinge, Pre-Engineered buildings designed & engineered with American & European Standards and codes consumes less steel than the designs done as per Indian Standards.

He also wants to highlight that the customers should understand that once the building has been manufactured it becomes very difficult to make any alterations or do additional loading on the structure.

He feels there may be demand of metal structure for multistory buildings for residential use, infrastructure works like bridges, airports and Malls etc. in time to come in India. The multinational (European) countries are more conscious than Indian about the green features of a building and we should also work on the same line. There is a perception shift for green buildings as now days, we see many multinational companies investing and setting their plants in India.

There is a vast scope for Pre-Engineered Buildings in upcoming market in the state of Maharashtra. The competition in the market for pre-engineered building is growing exponentially and we feel that good relations, better quality and timely finish will give an extra edge to the companies with the client .In the next few months we should see good growth in industries like cement, Steel, Pharmaceutical, Packaging and Automobile Industry . |

| |

|

|

|

|

| Steel Mutistorey Buildings: Floor system |

|

| |

Floor system comprises of a composite RCC slab cast over profiled metal deck supported on secondary steel beams which are provided with shear studs on the top flanges to generate the composite behavior . |

|

|

|

| |

|

|

| |

| Projects Won |

Projects Completed |

|

|

|

|

|

|

|

SMCC Constructions India Ltd in Gujarat |

|

Gamesa Renewable Pvt Ltd in Andhra Pradesh |

|

Thapar University in Punjab |

|

Lloyd Line Pipes Ltd in Maharashtra |

|

Anphar Organics Pvt Ltd in Jammu |

|

|

|

|

|

|

|

Sushil Udyog in Rajasthan |

|

Hindalco Industries Limited in Madhya Pradesh |

|

Casa Grande Distripark Pvt Ltd In Chennai |

|

Decathlon Sports Pvt Ltd in Odisha |

|

Innovative Tech Park Ltd. in Uttarakhand |

|

|

|

| |

|

|

| Interarch in Press: |

|

| |

|

|

|

|

| |

|

|

| Training at Interarch |

|

| |

|

|

Interarch organized training for Painters, Blaster men & Painting Supervisors in Pantnagar Plant on 12 Jan.,2016 |

|

|

| |

|

|

| Awards & Recognition |

|

| |

|

Intrarch Building Product was facilitated with the IDC Insights Iconic Awards 2015 in the category of Manufacturing Excellence in Innovation. The prestigious Insights awards honour the business and IT leaders who envisaged, conceptualized, and successfully executed an IT/Technology Implementation that brought about tangible results for their organization. The winners, after a rigorous evaluation process, were chosen independently based on the votes of the jury and final validation of the Jury Chair Person. Intrarch Building Product was facilitated with the IDC Insights Iconic Awards 2015 in the category of Manufacturing Excellence in Innovation. The prestigious Insights awards honour the business and IT leaders who envisaged, conceptualized, and successfully executed an IT/Technology Implementation that brought about tangible results for their organization. The winners, after a rigorous evaluation process, were chosen independently based on the votes of the jury and final validation of the Jury Chair Person.

IDC Insights Iconic Award 2015 was conferred to Mr. Shailendra Choudhary, Associate Vice President & Head of I.T. in Interarch Building Products; to recognize the outstanding contribution which is directly impacting competitive advantage, revenue growth and profitability through the leverage of

technological and digital tools and methods.

|

| |

|

|

|

|

| Building Made Possible in Steel: The New York Times Building, New York City |

|

| |

|

The steel-framed building, cruciform in plan, has a screen of 41.3 mm ceramic rods mounted on the exterior of the glass curtain wall on the east, west and south facades. The rod spacing increases from the base to the top, adding transparency as the building rises. The steel framing and bracing is exposed at the four corner "notches" of the building.

The tower was designed by Renzo Piano Building Workshop and FXFOWLE Architects, with Gensler providing interior design.

The steel-framed building, cruciform in plan, has a screen of 41.3 mm ceramic rods mounted on the exterior of the glass curtain wall on the east, west and south facades. The rod spacing increases from the base to the top, adding transparency as the building rises. The steel framing and bracing is exposed at the four corner "notches" of the building.

The tower was designed by Renzo Piano Building Workshop and FXFOWLE Architects, with Gensler providing interior design.

The tower rises 748 feet (228 m) from the street to its roof, with the exterior curtain wall extending 92 feet (28 m) higher to 840 feet (260 m), and a mast rising to 1,046 feet (319 m).

Sustainability

The new building is promoted as a green structure. The design incorporates numerous environmentally sustainable features for increased energy efficiency. The double skin curtain wall, automated louver shading system, dimmable lighting system, underfloor air distribution system and cogeneration are the main sustainable design features.

In excess of 95% of the structural steel was recycled.

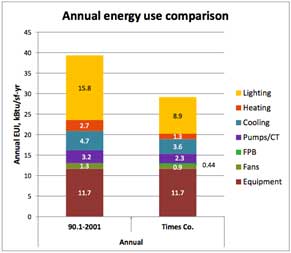

Overall Performance & Energy saved Overall Performance & Energy saved

A team of researchers at the Lawrence Berkeley National Lab and Center for the Built Environment monitored the building’s performance for a year and compared the results with buildings that meet with the standard building efficiency codes. They found that the New York Times Building significantly reduced annual electricity, cut heating energy use by more than 50% and decrease the peak electric demand as well. It is essential to start with a sound, integrated building design, and then to pay attention to details such as procurement of building equipment, and verifying the proper performance of the equipment after it is installed. The Times Company did its homework in 2004, well before construction began on the building, evaluating and optimizing the shading and daylighting technologies,concluded the Berkeley researchers. |

| |

|

| |

|

|

| |

|

|