|

|

| |

|

|

| Rain Water Harvesting Using Interarch Pre-Engineered Buildings |

|

| |

|

Metal roofs are an ideal platform for rainwater collection. The smoother, cleaner, and more impervious the roof surface, the higher the water quality and amount of water that can be collected. Galvanized steel sheets are highly suitable for water collection fit for human consumption. The rainwater is collected in guttering placed around the eaves of the building. A checklist that can be followed for installing gutters in the building Metal roofs are an ideal platform for rainwater collection. The smoother, cleaner, and more impervious the roof surface, the higher the water quality and amount of water that can be collected. Galvanized steel sheets are highly suitable for water collection fit for human consumption. The rainwater is collected in guttering placed around the eaves of the building. A checklist that can be followed for installing gutters in the building |

|

|

Select gutters that are 5 inches wide |

|

Select galvanized steel (22 gauge minimum) or aluminum (.025 inch minimum) gutters |

|

Slope gutters 1/16" per 1' of gutter, to enhance flow |

|

Use an expansion joint at the connection, if a straight run of gutter exceeds 40 feet |

|

Keep the front of the gutter one-half inch lower than the back |

|

Provide gutter hangers every 3 feet |

|

Do not exceed 45 degree angle bends in horizontal pipe runs |

|

Select elbows in 45, 60, 75, or 90 degree sizes |

|

|

|

|

|

| |

|

|

| How many buildings have Interarch executed for Automotive & Automotive Ancillary Sector |

|

| |

|

| Interarch has be integral part of India’s growing automotive industry. With our advance technology and superior engineering, we have executed more than 1500 Pre-Engineered Steel buildings for some of the biggest names in the Automotive Industry |

|

| Each building is designed keeping in mind quality and expert detailing for every application be it Paint Shop, Weld Shop ,Engine Shop , Assembly Shop , Conveyor Corridors, Canteens , Training Halls, warehouses or Office Buildings |

|

|

|

|

| |

|

|

|

| Project Management Tip |

|

| |

|

| Adverse weather conditions such as heavy rain, foggy conditions will impact the visibility of the lifting crew. It is advisable to stop all lifting operations as soon as the weather condition started deteriorating. Interarch advises no erection work to be carried out during rain. |

|

| Other practices which can be followed during monsoon season |

|

Raincoats are to be worn by all workers at site whenever rain is anticipated or during drizzling |

|

Once the rain is over site in-charge should take a Work Permit from in house safety officer and client safety officer to resume work |

|

Boom lifts are to be used during monsoon season |

|

Material to be stacked above ground level in order to avoid water logging |

|

Hot work like welding etc. to be prohibited during monsoon season |

|

Use of Crawler cranes is advised during monsoon season |

|

Materials like Insulation, Hardware, Paint, Galvanized Coils must be stored in a covered areas |

|

Tarpaulin must be used to cover the structural material to avoid paint peel off |

|

All painting work to be avoided during monsoon |

|

Roofing work should be avoided, and post rain project team should wait for the surface to get dry before starting the roofing work |

|

Throughout the monsoon season safety officer should be very vigilant and should thoroughly check all surfaces before allowing work to start after rain |

|

|

| |

|

|

|

|

| Project Spotlight: Symphonia & Graphics (P) Ltd. Bundi, Rajasthan |

|

| |

|

| Interarch supplied a warehouse building for Symphonia & Graphics (P) Ltd.at Bundi in Rajasthan with area covering more than 60,000 Sq. M. The scope of work included design & engineering, manufacturing, supply and erection of the Pre-Engineering Steel building. |

| |

|

|

| Key Project Highlight |

|

| Project Name |

Symphonia & Graphics (P) Ltd. |

| Project Location |

Bundi, Rajasthan |

| Project Usage |

Warehouse |

| Total Project Area |

60470 Sq M |

| No. of Buildings |

Building 1 |

Building 2 |

Building 3 |

Building 4 |

| Width |

73 M |

37.750 M |

73 M |

60.30 M |

| Length |

348.40 M |

102 M |

256.9 M |

206.20 M |

| Height |

5.6 M |

5.6 M |

5.6 M |

5.6 M |

| Special Features |

|

Rigid frame is considered on roof as per drawing provided by marketing. |

|

Flange brace of 50X50X6 is considered double side |

|

Flashing, trims , Eave gutters & downspouts |

|

Crane beam, brackets, Crane rail & crane |

|

Grouting below base plate & under column base plates with high strength |

|

Interior partition wall, doors and fixtures |

|

Seismic zone is II |

|

|

| |

|

|

| |

| Projects Completed |

Projects Won |

|

|

|

|

|

|

|

Shiv Gorakh Engineering Works in Rajasthan |

|

Systematic Conson Ltd in Noida |

|

IPF Vikram India Ltd in Madhya Pradesh |

|

British Paints in Assam |

|

Ozone Naturals in Haryana |

|

|

|

|

|

|

|

|

|

GE India Industrial Pvt Ltd in Maharashtra |

|

Chemo India Formulations Pvt Ltd In Andhra Pradesh |

|

Greenply Industries Ltd in Andhra Pradesh |

|

VE Commercial Vehicles Ltd in Madhya Pradesh |

|

Sudisa Foundry Pvt Ltd in Bihar |

|

|

| |

|

|

|

| Customer Testimonial |

|

| |

|

Interarch Building Products executed Pre-Engineered Building project of our Store Building at Kurukshetra in Haryana. We are satisfied with the work & happy with the timely completion of the project. Interarch Building Products executed Pre-Engineered Building project of our Store Building at Kurukshetra in Haryana. We are satisfied with the work & happy with the timely completion of the project.

We wish Interarch very best in all their future endeavors. |

|

| |

|

|

|

| Building Innovators Closed Group Seminar |

|

| |

|

| Interarch conducted Building Innovators Seminar on 1th July’16 in Pune, Maharashtra |

|

|

|

| |

|

|

| Event Participation: |

|

| |

|

| Interarch participated in the 6th edition of India Warehousing Show 2016 exhibition which was held at Pragati Maidan, New Delhi from 8 – 10 June 2016. The exhibition focused on Warehousing and Logistics industry. |

| |

|

|

|

|

|

|

| Tech Zone: Email Etiquette Rules Every Professional Should Know |

|

| |

|

|

Include a clear and direct subject line which should match the message |

|

Use a professional email address for official work |

|

Think twice before hitting replying to all, as half of people should not be marked in the male |

|

Use professional salutations only |

|

Be cautious with humor or loose comments |

|

Know that people from different cultures speak and write differently |

|

Reply to your emails with in a period of 24-36 hrs if not urgent |

|

Proofread every message before sending it |

|

Add the email address the last after subject |

|

Before sending the email, check again that you’ve selected the correct recipients |

|

Avoid using shortcuts to real words, emoticons, jargon, or slang |

|

| |

|

|

|

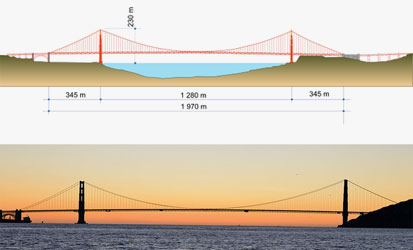

| Building made possible in Steel: Golden Gate Bridge in California: |

|

| |

|

| The construction of what was to become the world's largest suspension bridge was a colossal task. At the time many people did not believe it was technically possible to span the Golden Gate. It took thousands of workers, four years and 35 million dollars to complete the structure and bridge was open to public on May 27, 1937 |

|

| Design |

Suspension , Truss Arch & Truss Causeways |

| Material |

Steel |

| Total Length |

8,981 ft (2,737.4 m), about 1.7 mi (2.7 km) |

| Height |

746 ft (227.4 m) |

| Width |

90 ft( 27.4m) |

| Longest Span |

4,200 ft (1,280.2 m) |

| Vertical Clearance |

14 ft (4.3 m) at toll gates, Trucks cannot pass |

| Clearance below |

220 ft (67.1 m) at Tide |

|

| |

|

|

| Where was the steel fabricated for the construction of the golden gate bridge? |

| The fabricated steel used in the construction of the Golden Gate Bridge was manufactured by Bethlehem Steel in plants in Trenton, New Jersey and Sparrows Point, Maryland and in plants in three Pennsylvania towns: Bethlehem, Pottstown, and Steelton. The steel was loaded, in sections, onto rail cars, taken to Philadelphia and shipped through the Panama Canal to San Francisco. The shipment of the steel was timed to coincide with the construction of the bridge. |

|

|

|

| |

|

|