| If you are having troubles viewing this e-mailer, kindly "click here" for the online version. |

|

| |

|

| |

|

Dear Readers,

We are pleased to announce that with this issue of the newsletter we have completed vol. 5 and from next month onwards we will start with vol 6 with a new look & styling of the newsletter.

You can now find Interarch in all leading trade publications like Construction world , B2B Purchase , Construction week , MBN & CW, MGS Architecture , EPC World, Master Builder , CE & CR, The Cement Review, Cargo Connect to name a few

|

Thanks & Regards,

Arvind Nanda & Gautam Suri

Founder Directors - Interarch Building Products |

|

|

| |

| |

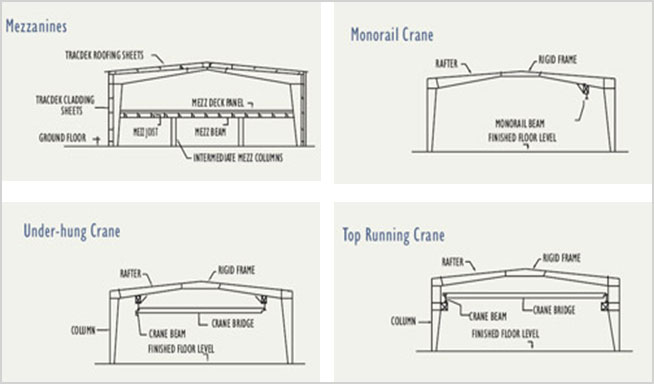

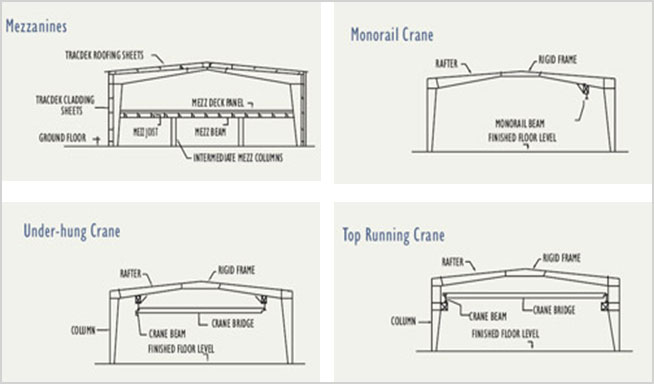

| Know your Interarch Pre- Engineered buildings: Cranes in Buildings |

| |

|

Interarch Pre-engineered buildings can be designed to accept most types of crane systems such as EOT, Monorail, Under-hung cranes and other load carrying devices like conveyors etc., in both clear-span and multi-span buildings. When a crane system is to be integrated, Interarch’s scope is limited to brackets and crane runway beams which support the crane system. Complete information on the crane system is required in order to design and estimate buildings with cranes |

|

|

|

| Interarch Heritage: The year 1984 |

| |

|

We have started a new section in this newsletter which will cover how the company has evolved from a small start-up in 1984 to one of the leading Pre-Engineered Steel building provider and strong brand name .This section will cover major milestone the company overtook to reach this level starting from 1984. We have started a new section in this newsletter which will cover how the company has evolved from a small start-up in 1984 to one of the leading Pre-Engineered Steel building provider and strong brand name .This section will cover major milestone the company overtook to reach this level starting from 1984.

In the year 1984, Interarch Building Products commenced operations with 3 employees, pioneering Metal Suspended Ceilings in India.

In the first year only Interarch won a very large and prestigious order for False Ceiling of Delhi Airport

|

| Interarch Light Gauge Framing System for Office Buildings: |

| |

| LGFS is ideal solution for this application with possibilities of various aesthetic finishes with any kind of shape, design and quality over conventional system. This system is ideal for Ground floor, G+ 1 & G+ 2 office buildings |

|

|

|

|

|

|

|

| Industry Knowledge Spokesperson: Ms Booma Pugazh |

| |

|

Ms Booma Pugazh is the Managing Director of BPDM Architects ,Engineers and Planners .Established in 1999 ,the firm has been holding the expertise in offering engineering design and consultancy with few major projects executed includes multistory commercial and residential complexes of India bull real estate & multistorey buildings for Om sai construction.

She feels that in abroad more sophisticated and good architectural shapes are used ,big size bending shapes are present in design(Curvilinear) and in its comparison to India Curvilinear Surfaces are absent as the buildings commonly have squared or rectangular shapes no other shapes could be seen in any of the PEB buildings in India. This is one point that she feels we need to change and start creating more innovative design in the coming years

As per her Interarch is good in terms of Quality, Erection capability, Delivery as compared to other competitors in the country. The size of the pre-engineered steel building industry in Maharashtra state will grow further as she feels that approx 35-40 % of Industrial architects, major consultants and architects now prefer PEB rather than RCC

|

| New Projects Won |

Projects Completed |

|

|

|

|

|

|

|

Sumeet Logistics & Industrial Park, Maharashtra |

|

Alstom India Limited, Harayana |

|

Hindalco Industries Ltd, M.P |

|

Bikaji Foods International Limited, Rajasthan |

|

Gamesa Wind Turbines Pvt Ltd, Gujarat |

|

VHM Industries Ltd, Maharashtra |

|

| |

|

|

|

|

|

|

Sansera Engineering Pvt Ltd. Karnataka |

|

Rishi Kiran Logisitcs,Gujarat |

|

Pioneer Land & infra, Haryana |

|

Superior Drinks Pvt. Ltd ,Maharastra |

|

Rudraksh Detergent & Chemicals Pvt ltd,Gujarat |

|

| |

|

| Continuous Improvement at Interarch: Enhance Key Skills |

| |

|

Training was organized in both plants in Uttarakhand (Pantnagar & Kichha) for supervisors, HODs,

Managers,Engineers & Office staff team. The objective of training was to enhance Key Skills,

Performance & how to provide proper feedback |

| |

|

| Interarch in Press |

Upcoming Events |

|

|

|

|

|

|

| Magazine: Buildings Construction Update |

|

|

| |

|

|

|

|

|

| Stall No. 16 at India Steel Expo in Mumbai on 16th -18th April 2010 |

|

|

| Interarch Building Innovator Seminar in Chandigarh on 24th April 2015 |

|

|

|

|

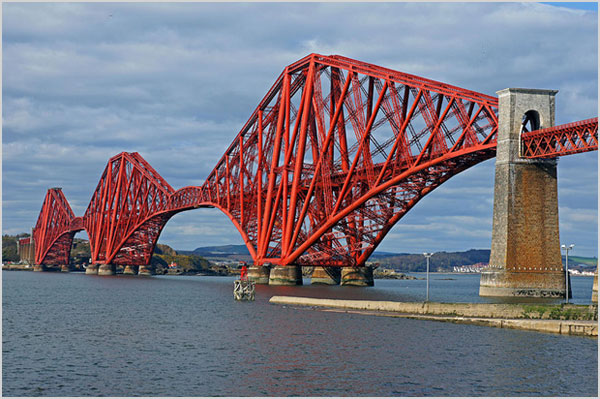

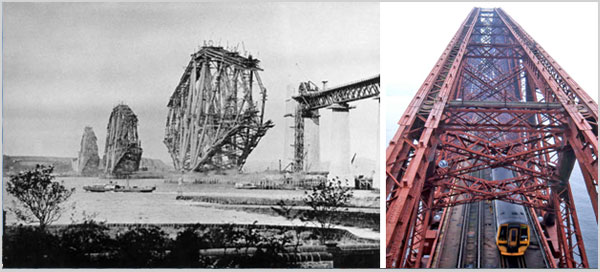

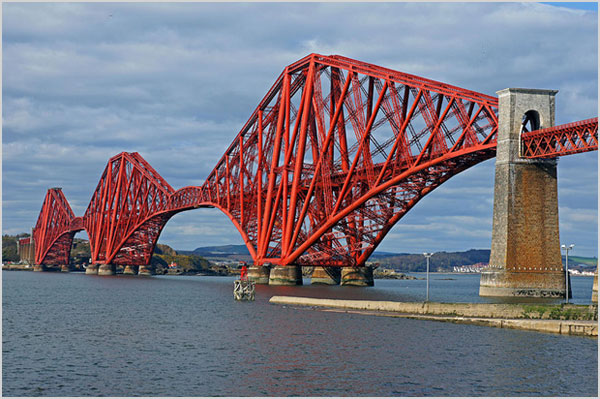

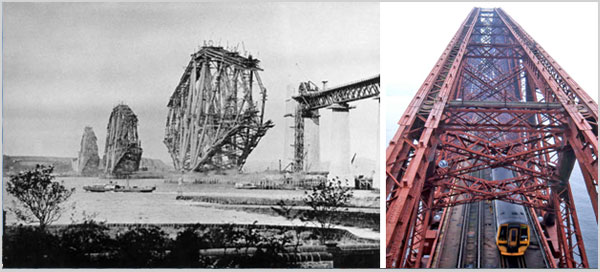

| Made in Steel: Forth Bridge, United Kingdom |

| |

|

Steel bridges now have a proven life span extending to well over 100 years. A notable example is the imposing Forth Rail Bridge in Scotland, which was completed in 1890. The scale and size of this significant landmark was a major achievement in construction engineering, and the structure has stood the test of time.

Steel has a predictable fatigue life and the structural elements are visible and accessible. Any signs of deterioration are readily apparent, without the need for extensive investigations. Corrosion is a surface effect, which rarely compromises the structural integrity of a bridge, and any problems may be swiftly addressed by repainting the affected areas.

Steel bridges now have a proven life span extending to well over 100 years. A notable example is the imposing Forth Rail Bridge in Scotland, which was completed in 1890. The scale and size of this significant landmark was a major achievement in construction engineering, and the structure has stood the test of time.

Steel has a predictable fatigue life and the structural elements are visible and accessible. Any signs of deterioration are readily apparent, without the need for extensive investigations. Corrosion is a surface effect, which rarely compromises the structural integrity of a bridge, and any problems may be swiftly addressed by repainting the affected areas.

Advances in coating technology and an industry commitment to the training of coating applicators mean that the latest protective systems are expected to last well beyond 30 years before requiring maintenance. Furthermore, the use of unpainted weathering steel, which requires almost no maintenance, is increasingly popular, as it is recognized as the ultimate low maintenance option for bridge construction

|

Design:

The Forth Bridge has three double cantilevers with two 1700ft suspended spans between them, at the time the longest bridge spans in the world. As required by the Admiralty, the rail level is 150ft (46m) above high water. Each of the towers has four steel tubes 12ft (3.7m) in diameter and reach to a height of 361ft (110m) above high water. Their foundations extend 89ft below this into the river bed, making the total height from foundations to the top of the towers 137 metres. The total length of the bridge, including its approach via ducts is 2,467 metres. The main structure itself measures 1,630 metres portal to portal.

Baker and Fowler’s bridge was the first major construction in Britain to be made from steel; the bridge incorporates 53,000 tonnes of the material. The design of the bridge was very carefully balanced, with allowance being made for a maximum thermal expansion of 16½ inches (420mm) over the 5350ft (1630m) steel central structure. It incorporated 6.5 million rivets, which aggregated 4,200 tons weight alone. It was designed to withstand a wind force of 56lb per square foot. |

| |

|

| |

|

|

|

|

|

|

Click here to submit your enquiry online |

|

| INTERARCH BUILDING PRODUCTS PVT. LTD.

Central Marketing Office, B-30, Sector 57, Noida - 201 301, India

Tel.: +91-120-4170200, 2581029 | Fax: +91-120-2581017 | E-mail: info@interarchbuildings.com |

visit us at: www.interarchbuildings.com, www.interarchinfra.com |

|

|

We have started a new section in this newsletter which will cover how the company has evolved from a small start-up in 1984 to one of the leading Pre-Engineered Steel building provider and strong brand name .This section will cover major milestone the company overtook to reach this level starting from 1984.

We have started a new section in this newsletter which will cover how the company has evolved from a small start-up in 1984 to one of the leading Pre-Engineered Steel building provider and strong brand name .This section will cover major milestone the company overtook to reach this level starting from 1984.

Steel bridges now have a proven life span extending to well over 100 years. A notable example is the imposing Forth Rail Bridge in Scotland, which was completed in 1890. The scale and size of this significant landmark was a major achievement in construction engineering, and the structure has stood the test of time.

Steel has a predictable fatigue life and the structural elements are visible and accessible. Any signs of deterioration are readily apparent, without the need for extensive investigations. Corrosion is a surface effect, which rarely compromises the structural integrity of a bridge, and any problems may be swiftly addressed by repainting the affected areas.

Steel bridges now have a proven life span extending to well over 100 years. A notable example is the imposing Forth Rail Bridge in Scotland, which was completed in 1890. The scale and size of this significant landmark was a major achievement in construction engineering, and the structure has stood the test of time.

Steel has a predictable fatigue life and the structural elements are visible and accessible. Any signs of deterioration are readily apparent, without the need for extensive investigations. Corrosion is a surface effect, which rarely compromises the structural integrity of a bridge, and any problems may be swiftly addressed by repainting the affected areas.