|

| |

|

| |

|

At Interarch we aim to provide best engineering, manufacturing and execution of heavy and light steel construction solutions for our customers.

We aim to train and mentor our teams and management at the highest levels to ensure best quality of projects to fulfill our customer satisfaction. This year we have

revised our quality policy to ensure that all the projects

will be delivered in the most efficient manner and we

wish to be the preferred choice of our customer.

|

Thanks & Regards,

Arvind Nanda & Gautam Suri

Founder Directors - Interarch Building Products |

|

|

| |

| |

| |

| |

Technology for Building Erection

By Vishal Khandelwal, DGM Design Interarch Infrastructure |

| |

|

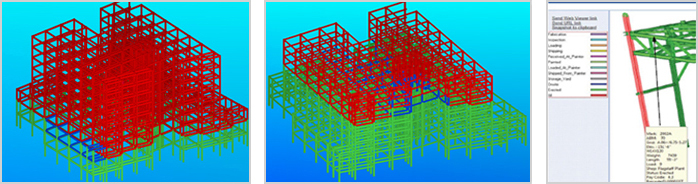

| Interarch uses some of the most advanced software to do 3D modeling and engineering of our structures. By integrating BIM into our standard workflow we increased the efficiency and value of the products without increasing the cost of the product to our valuable customers.

One example is the color coding of the member in the model for erection sequences due to this it becomes relatively simple to share the erection sequences with our project team members and customers. Coloring the model is a part of our standard process and practices and not something for some specific job like power plants and multistory buildings. Using this BIM data, don’t increase the cost of the products but it decreases our risks and increases our quality.

The two color-coded building model shown here illustrate the kind of 3D view available using the BIM data. |

|

|

|

Model showing a building before much of the steel erection. Members in red colors are yet to be erected. |

|

Model of the same building nearing to completion. Members in green color are erected |

|

With access to model, erection person can get very particular and detailed information for each members and components. |

|

|

| |

| Control Temperature Inside your Building |

| |

|

Insulation material is sandwiched and placed within walls or roof to prevent the temperature exchange from the building to the outside climate. Insulation material are used to keep the building cool when it’s warm outside and Insulation material is sandwiched and placed within walls or roof to prevent the temperature exchange from the building to the outside climate. Insulation material are used to keep the building cool when it’s warm outside and

warm when it’s cool outside.

Insulation recommend by Interarch Building Products |

|

|

| Glass wool (fiberglass) |

|

It is made from melted glass spun into a flexible mat of fine fibers |

|

Available in low densities and roll form with the reflective vapor barrier for convenient installation under metal roofs |

|

Excellent Compressibility |

| Rock wool |

|

It is made from mineral rock melted at high temperatures and spun into a mat of fine fibers. |

|

Available in higher densities |

|

Suitable for double skin roofing or roofing requiring walkable insulation |

|

|

|

|

| Turbo Ventilators - Turbo ventilators use the support of the wind outside and the heat being generated from inside. Wind creates a flow of air through turbine to enhance extraction. Turbo ventilators exchange the air from inside to outside.

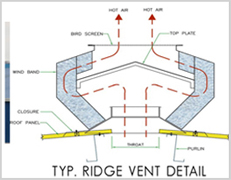

Ridge Ventilators - A ridge vent is a natural gravity ventilator installed at the peak of a sloped roof which allows warm, humid air to escape a building's attic. Ridge vents are most commonly used as a supplementary ventilation system in industrial building

Paint - The most harmful chemicals found in paint are Volatile Organic Compounds, or VOCs. VOCs are unstable, carbon-containing compounds that readily vaporize into the air. When they enter the air, they react with other elements to produce ozone, which causes air pollution and a host of health issues including breathing problems, headache, burning, watery eyes and nausea. Thus, Interarch uses Low VOC paints, which use water as a carrier instead of petroleum-based solvents. They contain reduced levels of VOCs, which emit smog producing pollutants into the air. This zero or low VOC paint has many benefits like |  |

|

|

|

Environment friendly, as there are lower levels of ozone pollution |

|

Fewer emissions of smog-forming chemicals |

|

Better indoor and outdoor air quality |

|

Allergies or sensitivities to these paints is uncommon |

|

Ideal for commercial applications, and offer excellent scrub ability |

|

Quick Drying |

|

Low Odour |

|

Non-yellowing |

|

Increased UV resistance, flexibility |

|  |

| Roof Monitor - A roof monitor consists of a flat roof section raised above the adjacent roof, with vertical glazing on at all sides of the raised bay. This arrangement can provide daylight in all directions, thus using more on natural lighting. Roof monitors also permit structural openings and support to provide fixity for forced ventilation systems when the number of air changes/hour required are high. |

|

| |

| Customer Testimonial |

| |

|

We appreciate your dedication & significant efforts to promote high standards of competence & compliance for occupation health & safety. This has contributed towards creating safety awareness among the employees in achieving the organization goal of "Zero Accident”.

We hope you will continue to contribute in future. We appreciate your dedication & significant efforts to promote high standards of competence & compliance for occupation health & safety. This has contributed towards creating safety awareness among the employees in achieving the organization goal of "Zero Accident”.

We hope you will continue to contribute in future.

|

|

| |

|

| |

| Industry Spokesperson - S.R. Patil Architects & Consultants |

| |

|

Mr. S R Patil a civil & structural engineer is the principal architect of SR Patil Architects & Consultants, which was established by him in 1965 as a Strctural Design firm. The firm got affiliation from Indian Institute of Architecture and Council of Architecture in 1972. He started architectural designing and became member of Structural Design of India. The firm has been holding the expertise in offering engineering & designing, leveraging upon the proficiency of experts, and gained competency in technology, construction, and engineering. Mr. S R Patil a civil & structural engineer is the principal architect of SR Patil Architects & Consultants, which was established by him in 1965 as a Strctural Design firm. The firm got affiliation from Indian Institute of Architecture and Council of Architecture in 1972. He started architectural designing and became member of Structural Design of India. The firm has been holding the expertise in offering engineering & designing, leveraging upon the proficiency of experts, and gained competency in technology, construction, and engineering.

According to Mr. S R Patil the size of the PEB industry in state will grow as PEB has a wide scope in future industrial architects, major consultants are aware of what PEB actually is, thus the size of steel buildings sector in Maharashtra region will raise.

Further he says, Green Buildings in India has positive upcoming scope as people now are much more smart and intelligent who prefers green buildings. People are considering the advantages and sustainability of green building that is why we can say that green building market is lucrative in the coming years.

|

|

| |

|

|

| |

| |

| New Project Wins |

| |

|

Tata Marcopolo Motors Limited, Karnataka |

|

|

Siemens Ltd, Andhra Pradesh |

|

Mahindra Two Wheelers Ltd, Madhya Pradesh |

|

Track Components Ltd, Karnataka |

|

Toyota India Ltd, Rajasthan |

|

| |

| Interarch In Press |

| |

|

B2B Purchase |

|

|

MGS Architecture |

|

Construction Week |

|

Construction World |

|

NBM & CW |

|

CE & CR |

|

SSMB |

|

| |

| Projects Completed |

| |

|

Panasonic India Pvt. Ltd, Haryana |

|

|

Groz Engineering Pvt. Ltd, Uttar Pradesh |

|

Severn Glocon India Pvt. Ltd, Tamil Nadu |

|

Musashi India Pvt. Ltd, Karnataka |

|

Pithampur Tools Pvt. Ltd, Madhya Pradesh |

|

| |

| Trivia Question of the month |

| |

| Q. In year 2007 which company presented Interarch with “best EHS practices certificate”, for achievement of 1.36 million safe man hours? |

| a) |

Asian Paints India Ltd. |

|

| b) |

Essar Steel Ltd. |

| c) |

Fiat India Automotive Ltd. |

| d) |

Tata Motors |

|

|

|

|

| |

|

|

|

| Events |

| |

| Interarch recently participated in Roof India Exhibition 2013, held at Bombay Exhibition Center from 24 May'13 - 26 May'13. |

|

|

|

|

|

|

|

|

Click here to submit your enquiry online |

|

| INTERARCH BUILDING PRODUCTS PVT. LTD.

Central Marketing Office, B-30, Sector 57, Noida - 201 301, India

Tel.: +91-120-4170200, 2581029 | Fax: +91-120-2581017 | E-mail: info@interarchbuildings.com |

visit us at: www.interarchbuildings.com , www.interarchinfra.com |

|

|