| If you are having troubles viewing this e-mailer, kindly "click here" for the online version. |

|

| |

|

| |

|

We are quite hopeful of the emerging market post the formation of new government. We believe and hope more focus will be given to infrastructure sector which is the most booming sector in the country.

We wish all the best to our readers, partners and other fellow marketers and look forward to some meaningful and significant working in the coming future.

Thanks & Regards,

Arvind Nanda & Gautam Suri

Founder Directors - Interarch Building Products

|

|

| |

| |

| Interarch’s Innovation in Steel |

| |

|

In 1992, Interarch pioneered colour-coated, engineered metal roof & wall systems in India. Since then, Interarch has been the leading manufacturer and provider of pre-engineered metal roof and wall systems that are used in some of the largest and most pristine projects of the country. With the most widespread network of authorized dealers, channel partners and erectors, Interarch is the largest supplier and installer of metal roofing systems in India.

Interarch offers various roofing profiles;

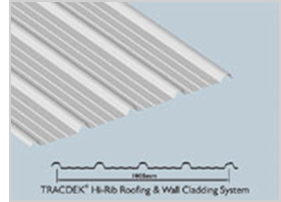

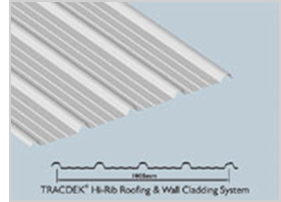

TRACDEK® Hi-Rib® TRACDEK® Hi-Rib®

It is a pierced fixed roof and wall covering system, consists of structurally-engineered profiled panels that are available in single length (up to 12 meters) and are fixed by means of self-drilling fasteners. All the ribs are clipped on and are interlocked. No penetration is done for its fixation to the roof or wall framing.

The patented fluted side lap makes TRACDEK® Hi-Rib® completely watertight. The side lap is totally weatherproof. Any moisture drawn in by capillary action is trapped and dispersed by normal run-off.

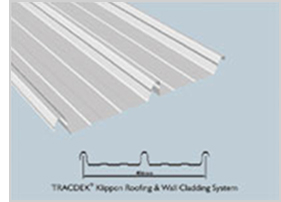

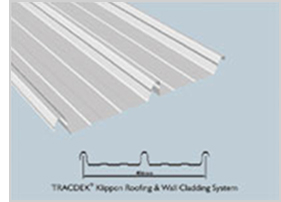

TRACDEK®Klippon®

TRACDEK®Klippon® is a concealed fixed snap-on seam roof/wall covering system that consists of structurally strong high-ribbed panels with wide-fluted pans for efficient water shedding and are fixed by means of concealed clips. All the ribs are clipped on and are interlocked. No penetration is done for its fixation to the roof or wall framing. These are ideally suited for regions which receive heavy rainfall and can be used on slopes as low as 1 in 20. TRACDEK®Klippon® is a concealed fixed snap-on seam roof/wall covering system that consists of structurally strong high-ribbed panels with wide-fluted pans for efficient water shedding and are fixed by means of concealed clips. All the ribs are clipped on and are interlocked. No penetration is done for its fixation to the roof or wall framing. These are ideally suited for regions which receive heavy rainfall and can be used on slopes as low as 1 in 20.

The clip-on side lap makes the Klippon® profile completely water-tight. The side lap is totally weatherproof. Any moisture drawn in by capillary action is trapped and dispersed by normal run-off.

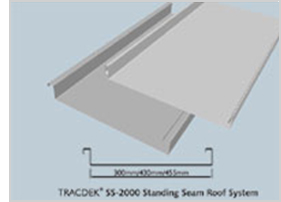

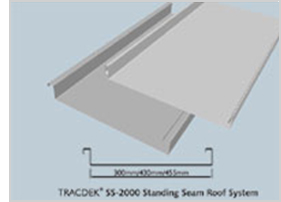

TRACDEK® SS-2000® TRACDEK® SS-2000®

TRACDEK® SS-2000®, also known as TRACDEK® Vertical Leg Structural Standing Seam Roof System, blends the aesthetics of an architectural panel with the strength of a structural panel. These panels have good uplift ratings assuring the reliability of the roof and can go down to roof slopes of up to 1:50. The designer is thus afforded

a flexible tool to meet any design challenge.

|

| Project Spotlight - Sat Prakash Sharma & Company |

| |

|

|

|

| Project Name |

Sat Prakash Sharma & Company |

| Project Location |

Jamalpur, Haryana |

| Building Usage |

Warehouse |

| Tonnage |

600 MT |

| Area |

29376 Sq. M |

| Width |

102 M |

| Length |

288 M |

| Height |

11 M clear |

| Roof Slope |

1:25 |

| Roofing Profile |

Tracdek Standing Seam 2000 |

| Sheeting Profile |

Tracdek Hi - Rib |

| Mezzanine |

The building delivered has 4 mezzanines of area 102 Sq. M each for live loads of 3 KN/ Sq. M and dead load of 100 mm thick RCC |

|

|

|

|

|

|

Customer Testimonial |

Did you know? |

| |

|

|

| Interarch delivered its largest clear span of 77.6 M for Utkal Alumina International building, Odisha. The building has an area of 11407 Sq. M and length 147 M and height 23 M. It is a coal shed designed, manufactured and excuted by Interarch in the year 2013. The steel tonnage used was 810 MT approximately. |

| |

|

| |

| |

|

| Industry Spokesperson - V.V. Sapre Consultants Pvt. Ltd., Indore |

| |

|

V.V. Sapre Consultants Pvt. Ltd. is a professional engineering consultancy company started in April 1991. It is liead by Mr. V.V. Sapre providing specialized and expert consulting in Civil & Structural Engineering services for all types of structures and buildings. He has been associated with Interarch from last 5years and worked on many projects with us in the past.

V.V. Sapre Consultants Pvt. Ltd. is a professional engineering consultancy company started in April 1991. It is liead by Mr. V.V. Sapre providing specialized and expert consulting in Civil & Structural Engineering services for all types of structures and buildings. He has been associated with Interarch from last 5years and worked on many projects with us in the past.

V.V. Sapre Consultants designed a project for JaideepIspat& Alloys Pvt. Ltd., Pithampur. which was a Steel Melting & Billet Casting project.

The project area was 5,700 Sq. m and project was completed within time schedule of 15 months including machine & equipment installation.

As per him, major complexity in the project was the interface of conventional building which is 42 m width *25 m height and Pre-Engineered building which is 25 m width x 9 m height. Also there was common civil foundation designed which was complex and heavy in nature to take care for EOT cranes of 75 Mt capacity in conventional structure and EOT crane of 10 Mt capacity in Pre-Engineered Building structure. |

| Building Made Possible in Steel: Willis Tower (Formerly the Sears Tower) |

|

|

| |

|

America’s building boom tailed off during the 1970s, but not before the monolithic Sears Tower America’s building boom tailed off during the 1970s, but not before the monolithic Sears Tower

was erected in Chicago.Using Khan’s Bundled Tube structural engineering principles, the building takes its strength from the combination of nine main structures arranged in a three by three grid

that make up the complex.

It’s a clever arrangement: all towers rise to 50-storeys where the northeast and southwest

buildings stop. The remaining seven towers continue to the 66th floor where the northeast and southwest structures end, and at 90-storeys, the north, south and east floors top out. The two remaining towers, the west and central towers then stretch to 110 floors, the building’s top. A

similar system of bundled towers was used by SOM to construct the BurjKhalifa.

Work started on construction of the Sears Tower in 1970 and the building was finished three years later. The Sears naming rights ran out in 2003 and in 2009, London-based insurance broker Willis Group Holdings agreed to lease a portion of the building and take over the naming rights.

The boxes are mounted within a steel frame and can be retracted back in to the building for cleaning.

Building Location: Chicago

Building Usage: office

Height: 442m

Number of storeys: 110

|

|

| Trivia Question of the Month |

|

|

| What is the total number of buildings delivered by Interarch till now? |

|

|

|

4000 |

|

5000 |

|

6000 |

|

3000 |

| Correct answer to the last week question is ; Largest clear span delivered by Interarch is 77M |

|

|

|

| |

| New Project Wins |

| |

|

Kathmandu University, Nepal |

|

|

IPCA Laboratories, Maharashtra |

|

Bhabani Pigments Private Limited, Haryana |

|

Ashirvad Pipes Private Limited, Karnataka |

|

Tegan Texofab Private Limited, Gujarat |

|

| |

| Projects Completed |

| |

|

Suprint Textiles Private Limited, Rajasthan |

|

|

Kakade Stone Crusher, Maharashtra |

|

Kodambi Trades, Madhya Pradesh |

|

JCB India Limited, Rajasthan |

|

Grasim Industries Limited, Madhya Pradesh |

|

| |

| Press Coverage |

| |

|

EPC World |

|

B2B Purchase |

|

Construction Mirror |

|

|

|

| |

| Events at Interarch |

| |

| Interarch participated in Roof India exhibition, Chennai from 13th May to 16 May to showcase the pre- engineered building segment and steel structures construction through Interarch Infra division. |

|

|

|

|

|

| Interarch conducted its Annual Sports and Cultural Meet 2014 in Tamil Nadu Plant to celebrate the successful completion of 30 years of existence of Interarch in the industry. |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

Click here to submit your enquiry online |

|

| INTERARCH BUILDING PRODUCTS PVT. LTD.

Central Marketing Office, B-30, Sector 57, Noida - 201 301, India

Tel.: +91-120-4170200, 2581029 | Fax: +91-120-2581017 | E-mail: info@interarchbuildings.com |

visit us at: www.interarchbuildings.com , www.interarchinfra.com |

|

|

TRACDEK® Hi-Rib®

TRACDEK® Hi-Rib® TRACDEK®Klippon® is a concealed fixed snap-on seam roof/wall covering system that consists of structurally strong high-ribbed panels with wide-fluted pans for efficient water shedding and are fixed by means of concealed clips. All the ribs are clipped on and are interlocked. No penetration is done for its fixation to the roof or wall framing. These are ideally suited for regions which receive heavy rainfall and can be used on slopes as low as 1 in 20.

TRACDEK®Klippon® is a concealed fixed snap-on seam roof/wall covering system that consists of structurally strong high-ribbed panels with wide-fluted pans for efficient water shedding and are fixed by means of concealed clips. All the ribs are clipped on and are interlocked. No penetration is done for its fixation to the roof or wall framing. These are ideally suited for regions which receive heavy rainfall and can be used on slopes as low as 1 in 20. TRACDEK® SS-2000®

TRACDEK® SS-2000®

V.V. Sapre Consultants Pvt. Ltd. is a professional engineering consultancy company started in April 1991. It is liead by Mr. V.V. Sapre providing specialized and expert consulting in Civil & Structural Engineering services for all types of structures and buildings. He has been associated with Interarch from last 5years and worked on many projects with us in the past.

V.V. Sapre Consultants Pvt. Ltd. is a professional engineering consultancy company started in April 1991. It is liead by Mr. V.V. Sapre providing specialized and expert consulting in Civil & Structural Engineering services for all types of structures and buildings. He has been associated with Interarch from last 5years and worked on many projects with us in the past.

America’s building boom tailed off during the 1970s, but not before the monolithic Sears Tower

America’s building boom tailed off during the 1970s, but not before the monolithic Sears Tower