| If you are having troubles viewing this e-mailer, kindly "click here" for the online version. |

|

| |

| |

|

Director's Epistle

| |

Dear Readers, Dear Readers,

Interarch Building Products and all its employees would like to wish all our readers and their families a very prosperous and Happy Diwali

May this auspicious occasion bring joy and prosperity in all your future endeavors

|

|

| |

Best Regards,

Arvind Nanda & Gautam Suri

Founder Directors - Interarch Building Products

|

|

Hi-Rib Roofing System Hi-Rib Roofing System |

| |

|

|

| |

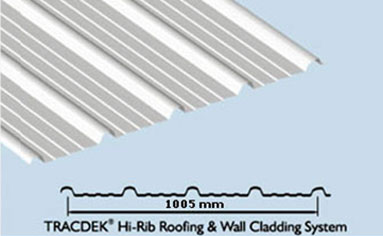

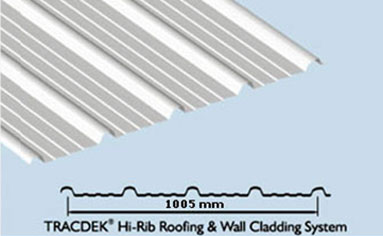

- Trackdek® Hi-Rib provides the feasibility for variety of finishes for attractive roofing and cladding of Domestic, Commercial & Industrial Applications.

- The patented fluted side lap makes TRACDEK® Hi-Rib Completely water tight. Any moisture drawn in by capillary action is trapped and dispersed by normal run-off.

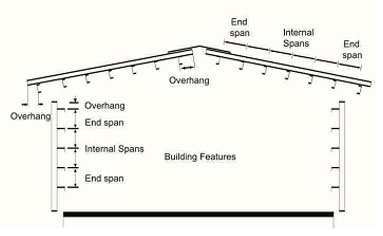

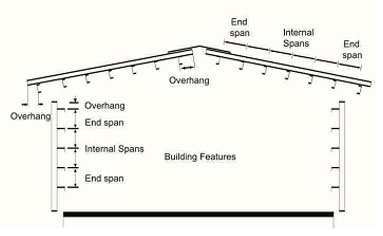

- Long Lengths and weather proof side lap allows TRACKDEK® Hi-Rib to

be used safely on roof pitches as low as 3 degree (approx. 1 in 20) in single sheets length & 5 degree (approx. 1 in 11) with end laps, and for vertical cladding.

- This Profile provides versatility and creativity to bring new and refreshing design to commercial, industrial and domestic buildings

- It is also available in crimp curved sections and can be given curvatures.

Technical Specification Standard Execution

- Wind Loads determined for Trackdek® are in accordance with IS - 875 (part 3)

- 1987 for regional wind velocity of 47 m/s for buildings up to 10 m high in

terrain category 3 and assuming an internal pressure coefficient of +0.2.

- Support spacing for roofs are generally governed by foot traffic for low pitch

roofs and by wind loading for high pitch roofs.

Benefits of Trackdek® Hi-Rib

- Long Life: It is manufactured with High Quality Galvalume Steel. The high performance organic coatings give Trackdek® long life even in Coastal areas

- High Strength: Tracdek® profiles provide excellent spanning ability and remarkable recovery after excessive load

- Economical: The long spanning ability and more coverage per unit mass permits wide support spacing, enabling supporting structure economies.

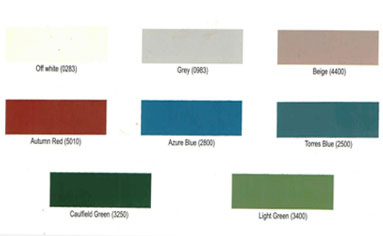

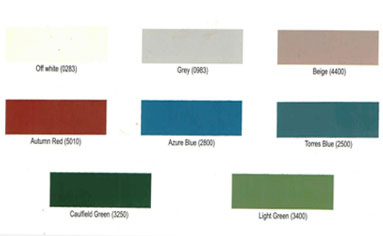

Available in Different Colors

|

| |

Total Coated Thickness (mm) |

Approx. mass per unit area Kg/m2 |

Approx. coverage m2/ton |

| Bare Galvalume® high tensile steel |

0.47 |

4.12 |

242 |

| Galvalume® high tensile strength |

0.50 |

4.24 |

235 |

| Galvanized steel, Color Coated |

0.50 |

4.56 |

219 |

| Galvanized steel, Color Coated |

0.55 |

5.03 |

198 |

| Galvanized steel, Color Coated |

0.65 |

5.97 |

167 |

|

|

| Interarch Contribution to the Environment: Life cycle assessment (LCA) |

| |

|

|

| |

A life cycle assessment (LCA) can help avoid a narrow outlook on environmental, social and economic concerns by assessing a full range of impacts associated with all cradle-to-grave stages of a process: from extraction of raw materials through materials processing, manufacture, distribution, use, repair and maintenance, and disposal or recycling. Impacts taken into account include (among others) embodied energy, global warming potential, resource use, air pollution, water pollution, and waste.

In terms of green building, the last few years have seen a shift away from a prescriptive approach, which assumes that certain prescribed practices are better for the environment, toward the scientific evaluation of actual performance through LCA.

Although LCA is widely recognized as the best way to evaluate the environmental impacts of buildings (ISO 14040 provides a recognized LCA methodology), it is not yet a consistent requirement of green building rating systems and codes, despite the fact that embodied energy and other life cycle impacts are critical to the design of environmentally responsible buildings.

For more details on the same kindly visit the webisites of Indian Green Building Council at www.igbc.in. |

|

|

|

| Trivia Question of the Month: October 2012 |

| |

|

|

| |

Q1. Which year and which company made first the Pre-Engineered Steel Multi-Storey Office complex in India Engineered, Manufactured and Delivered by Interarch

| Company |

Year |

| Option 1) TATA Motors Ltd |

Option 5) 1998 |

| Option 2) Reliance Industries Ltd |

Option 6) 2001 |

| Option 3) Mahindra Ltd |

Option 7) 2003 |

| Option 4) Aditya Birla Corporation |

Option 8) 2006 |

Kindly log on to http://www.facebook.com/interarchbuildings and provide the correct answer, Choose one option between 1-4 for company name and 5-8 for year. Winner will be announced in next month newsletter.

|

|

| |

|

|

|

|

How many quality checks are conducted during manufacturing process of Pre-Engineered Buildings by Interarch |

| |

|

|

| |

There are 5 types of quality checks that are conducted in a manufacturing process of Pre-Engineered Building by Interarch Building Products.

- Dimensional Inspection (DI) – Interarch ensures 100% DI of all fabricated built-up items as per Manufacture Shop drawing. All inspection activities are carried out in calibrated measuring instruments.

- Visual Inspection (VI) – Interarch ensures 100% Visual Inspection for any welding defect, straightness, notches, burrs, waviness, sweep camber, twisting, finishing, etc. for all fabricated built-up items.

- Ultrasonic Testing of Welding Joints (UT) – Ultrasonic Testing is carried out by Ultrasonic Flaw Detector machine by certified N.D.T level 2 persons on flange butt welds and other Complete Joints Penetration (CJP) weld joints. As per frequency mentioned in quality plan.

Di-penetrate Testing (DP) – This test is carried out on all critical weld joints by qualified operators. Testing frequency is kept as per quality norms

- Dry Film Thickness Primer & Paint (DFT) – It is a measuring unit of primer / paint coating in micromes. This test is performed by trained operator with calibrated Elcometer on all structural members randomly to ensure the fulfillment of customer requirement.

Congratulations to Winners of our Trivia Question of September 2012- Mr. Rohit Panchal, Mr. Ashish Kalra, Mr. Manu Prajapati, Mr. Chetan Arya & Mr. Vatsal Bulsara

|

|

|

| Technical Spotlight: Toyota Kirloskar Pvt Ltd. |

| |

|

|

| |

| Interarch has engineered, manufactured & delivered a Pre Engineered Building for Toyota Kirloskar Pvt. Ltd. for their plant in Bangalore.

One single building is divided into 7 areas where in the dimension of each area is different. Due to change in the dimension of these areas the complexity of the building increases. Special features of the building are as follows

| Building Location |

Bangalore |

| No. of Buildings |

1 building divided in North & South Block |

| Building Usage |

Paint Shop |

| Tonnage of Building |

1700 MT |

| Sheeting Supplied |

7500 Sq. M |

| Building Area |

5800 Sq. M |

| Width |

Area - (01 , 02 ,03 ) – 12.0 m Area - (04 , 05 ,06 ) – 15.0 m Area – (07) - 9.0 m |

| Features |

- Main Building is divided in 7 areas each having a different height Ar1- 12 M, Ar2-18 M, Ar3- 6.5 M, Ar4-16.5 M, Ar5- 25.2 M, Ar6-16.5M, Ar7-4.5 M.

- Length of each area is also different Ar1-18, Ar2- 117 M, Ar3- 42M, Ar4-18 M, Ar5-180 M, Ar6 – 15M, Ar7 - 39.0 M

- Ar1 - This area of the building has full Mezzanine with supporting Cable tray & pipe rack arrangement from column & rafter at different level.

- Ar2 - in this area half the portion is with mezzanine and half is without the mezzanine & Process Rail Beam is running at 18.2 m in Full length of this area with supporting beam at every 3.0 m interval with supporting Cable tray & pipe rack arrangement from column & rafter at different level.

- Ar3 - This area is connected to an existing building. In this area five different types of frames are designed.

- Ar4 - This area of the building has full Mezzanine with supporting Cable tray & pipe rack arrangement from columns & rafters at different level. It has a landing deck at the top level (above 16.5 M).

- Ar5 - we have installed a 26 M Jack Portal which is welded at site and 2 beams of 13 M each separately.

- The new building being made will connect to the existing building through a link bridge.

- North Block has a 15 M mezzanine at a height of 18.2 M.

- a. Special provisions for Process Equipment at 5.7 m level in full length of this area.

- b. Special provisions for Steel Girders at 6.8 & 10.8 m level in full length of this area.

- c. Process Rail Beam is running at 18.2 m in Full length of this area with supporting beam at every 3.0 m interval with supporting Cable tray & pipe rack arrangement from column & rafter at different level.

- d. Special Provision for AHU unit supporting from rafter in 2 bays of this area.

- Ar6 - This area of the building has full Mezzanine with supporting Cable tray & pipe rack arrangement from columns & rafters at different levels.

- Ar7 - This area is separate & having AHU unit loading..

- 19 M high staircase is provided in this building.

|

|

|

|

|

|

| |

|

| “Delivering Value”: Life Cycle Cost advantage with Pre-Engineered Steel Buildings:

By - Vikas Kaushal, Vice President-Marketing, Interarch Building Products

|

| |

|

|

| |

The performance of an industrial building is measured in terms of its life and the protection it provides to the

occupants from weather conditions so as to enable the factory operations to run continuously without any interference of weather effect such as rain, wind etc. Periodic maintenance is therefore required to keep this performance intact over a period of time. This maintenance involves water proofing in case of RCC Slab flat roof buildings, replacement

of damaged sheets in case of conventional steel truss sloped roof structures with Asbestoses cement corrugated (ACC) sheets Or replacement to Corrugated galvanized steel (CGI) sheets which have corroded due to action of weather.

Therefore over the Life of a building which is considered approximately 50 years, the Life cycle cost of the building is

calculated as follows:

Life cycle cost = Initial Construction cost + Periodic Maintenance cost

Even if we assume the initial cost of construction of a Pre-engineered steel building and conventionally site fabricated steel structure or a RCC building as the same, Life cycle cost of a Pre-Engineered Buildings is much lower. This is due to very low maintenance requirement in a Pre-Engineered Steel Building System as compared to conventionally site fabricated steel structure with an asbestos cement (AC) roofing sheet or a locally procured corrugated galvanized iron (CGI) sheet OR even RCC Slab casted flat roof building which requires annual water proofing within few years of construction. Even if we assume the initial cost of construction of a Pre-engineered steel building and conventionally site fabricated steel structure or a RCC building as the same, Life cycle cost of a Pre-Engineered Buildings is much lower. This is due to very low maintenance requirement in a Pre-Engineered Steel Building System as compared to conventionally site fabricated steel structure with an asbestos cement (AC) roofing sheet or a locally procured corrugated galvanized iron (CGI) sheet OR even RCC Slab casted flat roof building which requires annual water proofing within few years of construction.

Pre-engineered steel buildings as a standard are provided with very high quality steel roofing

and wall cladding cover in form of, profiled sheets manufactured out of high tensile strength, Galvalume steel coils. Galvalume is a special protective coating of Aluminium and Zinc alloy (AZ 150 - Coating Class) which enhances the life of steel by 4 to 5 times against life to first maintenance. |

- Galvalume steel roofing profiles are sold with a 15 years warrantee of life to first maintenance against corrosion.

- As the buildings are detailed by experienced professionals, Pre-Engineered Building Companies give in an average 10 years warrantee against leakages from roof.

- Galvalume Steel sheets are 50% lighter in weight (4 Kg/ Sq. M) as compared to Asbestoses cement sheets (8 Kg) therefore reducing the overall dead weight on the roof structure.

|

|

|

|

| Customer Testimony: DB Corp Ltd. |

| |

|

|

| |

This is to Appreciate Interarch Building Products for their exceptional project work for our (M/s DB Corp. Ltd.) Warehouse building in Jaipur, Rajasthan. We appreciate their team efforts & co-ordination and are profoundly pleased with the overall project management and execution capabilities of INTERARCH.

We have utmost confidence in Interarch’s expertise and wish to continue our partnership for future projects

We thank INTERARCH for the great work and wish them best of luck for all their future endeavors This is to Appreciate Interarch Building Products for their exceptional project work for our (M/s DB Corp. Ltd.) Warehouse building in Jaipur, Rajasthan. We appreciate their team efforts & co-ordination and are profoundly pleased with the overall project management and execution capabilities of INTERARCH.

We have utmost confidence in Interarch’s expertise and wish to continue our partnership for future projects

We thank INTERARCH for the great work and wish them best of luck for all their future endeavors

|

|

| |

|

|

|

|

Major Project Wins

- Hindustan Aqua Limited

- Mahle Engine Components India Pvt. Limited

- HEG Limited

- Praja Mechanicals Pvt Limited

- Wheels India Limited

Major Projects Completed

- Vectus Industries Limited

- Timken India Manufacturing Pvt. Limited

- Mrs. Rajashree, Mrs. Jayashree & Mrs. Padmashree

- Toyota Kirloskar Motors Pvt. Limited

- Tristar Infrastructure Pvt. Ltd.

Upcoming Event at Interarch Building Products

- Interarch is pleased to announce its upcoming Building Innovators Forum in Uttrakhand & Kolkata.

|

Awards & Recognition Won by Interarch

| |

|

Certificate of Appreciation awarded to Interarch Building Products by Tristar Infrastructure Pvt. Ltd.

This Certificate was awarded to Interarch Building Products Pvt. Ltd. on this date of 16 Oct 2012 for the Safety practices followed at site while delivering the project under the Supervision of Team Leader - Mr. Yogesh Vinze & Safety Officer - Mr. Rajesh Prajapati

|

|

| Interarch Building Products in Press |

| |

- MGS Architecture

- Projects Vendor

- Steel Structures & Metal Buildings

- B2B Purchase

|

|

| Building Made Possible In Steel: Willis Tower |

| |

- Building Usage - Commercial Space

- No. of Floors 108 + 3 Floors of basement

- Structural Material - Steel

- Tonnage of Building - 76000 Tonnes

- Total Area - 279000 Sq. M

- Architectural Height - 442.14 M or 1450 ft.

- Height till the Tip - 527 m or 1729 Ft

- No. Of Elevators - 104

- The structure is formed from 9 bundled square tubes, each 75 feet wide with no columns between the core and perimeter. Two of the tubes are 50 floors high, two are 66 floors, three are 90, and two are 108

- The lobby contains the moving sculpture "The Universe" by Alexander Calder

- The design for the Willis Tower incorporates nine steel-unit square tubes in a 3 tube by 3 tube arrangement, with each tube having the footprint of 75 × 75 feet (22 × 22 m). The Willis Tower was the first building for which this design was used. The design allows future growth of extra height to the tower if wanted or needed

- The building, meets the Leadership in Energy and Environmental Design (LEED) criteria, will undertake sustainability initiatives above and beyond those used by the United Stated Green Building Council to rate a green building.

- The reduction in energy use and CO2 emissions realized through the sustainability and modernization for the tower also brought economic opportunities by creating more than 3,600 jobs.

- Solar panels on the 90th floor roof to heat water for restrooms.

- Smart lighting systems that automatically dim when sunlight is available.

|

|

|

INTERARCH BUILDING PRODUCTS PVT. LTD., Central Marketing Office, B-30, Sector 57, NOIDA - 201 301, INDIA

Tel.: +91-120-4170200, 2581029, Fax: +91-120-2581017, E-mail: info@interarchbuildings.com

visit us at: www.interarchbuildings.com, www.facebook.com/interarchbuildings   |

|

Hi-Rib Roofing System

Hi-Rib Roofing System

This is to Appreciate Interarch Building Products for their exceptional project work for our (M/s DB Corp. Ltd.) Warehouse building in Jaipur, Rajasthan. We appreciate their team efforts & co-ordination and are profoundly pleased with the overall project management and execution capabilities of INTERARCH.

We have utmost confidence in Interarch’s expertise and wish to continue our partnership for future projects

We thank INTERARCH for the great work and wish them best of luck for all their future endeavors

This is to Appreciate Interarch Building Products for their exceptional project work for our (M/s DB Corp. Ltd.) Warehouse building in Jaipur, Rajasthan. We appreciate their team efforts & co-ordination and are profoundly pleased with the overall project management and execution capabilities of INTERARCH.

We have utmost confidence in Interarch’s expertise and wish to continue our partnership for future projects

We thank INTERARCH for the great work and wish them best of luck for all their future endeavors

Dear Readers,

Dear Readers,

Even if we assume the initial cost of construction of a Pre-engineered steel building and conventionally site fabricated steel structure or a RCC building as the same, Life cycle cost of a Pre-Engineered Buildings is much lower. This is due to very low maintenance requirement in a Pre-Engineered Steel Building System as compared to conventionally site fabricated steel structure with an asbestos cement (AC) roofing sheet or a locally procured corrugated galvanized iron (CGI) sheet OR even RCC Slab casted flat roof building which requires annual water proofing within few years of construction.

Even if we assume the initial cost of construction of a Pre-engineered steel building and conventionally site fabricated steel structure or a RCC building as the same, Life cycle cost of a Pre-Engineered Buildings is much lower. This is due to very low maintenance requirement in a Pre-Engineered Steel Building System as compared to conventionally site fabricated steel structure with an asbestos cement (AC) roofing sheet or a locally procured corrugated galvanized iron (CGI) sheet OR even RCC Slab casted flat roof building which requires annual water proofing within few years of construction.