| If you are having troubles viewing this e-mailer, kindly "click here" for the online version. |

|

| |

|

| |

|

We would like thank all our builders, partners and erectors for attending our 6th Annual Project Meet held in Delhi on 24th September. Our aim through this platform is to train and mentor our teams and management at the highest levels to ensure best quality of projects to fulfill customer satisfaction.

We look forward to a successful year of Safe and Quality construction with our partners.

Thanks & Regards,

Arvind Nanda & Gautam Suri

Founder Directors - Interarch Building Products

|

|

| |

| |

| |

| Project Management Capabilities at Interarch |

| |

|

Over the years, Interarch has successfully achieved a benchmark in providing best Project Management System in the industry for effective execution of projects within the desired timelines. The company has in place, an exhaus- Over the years, Interarch has successfully achieved a benchmark in providing best Project Management System in the industry for effective execution of projects within the desired timelines. The company has in place, an exhaus-

tive Quality Management System, a proper design management system for products following national and international standard requirements and stringent safety standards followed at site under the supervision of Safety supervisors allotted to each site. At Interarch we ensure stringent quality checks which are carried out at every step from manufacturing to delivery of project. Regular training sessions are conducted in all our plants for each worker to ensure proper implementation of quality and safety requirements at sites. Interarch in the recent past has received various safety and quality awards from its clients. We believe in delivering the best of our capabilities within the desired timeline. |

| PEB Construction in India a Way Forward |

| |

|

The Indian Pre-Engineered Steel Buildings (PEB) market is experiencing robust growth fuelled by infrastructure development and the increasing popularity of PEB systems in the industrial sector. It has been an interesting journey for the PEB industry over the last almost three decades in terms of observing the changing trends in the Indian construction industry. There have been times when pre-engineered solutions were not much in demand, but, gradually with the due course of time, people are becoming more aware and inclined towards it. The Indian Pre-Engineered Steel Buildings (PEB) market is experiencing robust growth fuelled by infrastructure development and the increasing popularity of PEB systems in the industrial sector. It has been an interesting journey for the PEB industry over the last almost three decades in terms of observing the changing trends in the Indian construction industry. There have been times when pre-engineered solutions were not much in demand, but, gradually with the due course of time, people are becoming more aware and inclined towards it.

Stemming from the PEB industry, what is taking shape is the new Heavy Engineering and larger Infrastructure projects which is the next in line for the infrastructural development of the country. Projects like Airports, International terminals, power plants, ports etc. require heavy steel structures and a different approach in comparison to PEB. PEB solutions are a perfect fit for large scale construction of airports, ports, warehousing sites as well as for power stations. The format of these buildings as well as the required timelines and quality of construction is natural advantages. With the complete three sixty degree view of a building structure right from the engineering to manufacturing at plants and final assembling at site, PEB buildings in infrastructure industry has got a good potential in the coming years. |

| Tracdek Metal Roof & Wall Systems |

| |

|

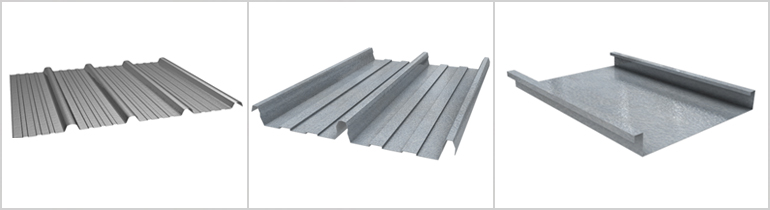

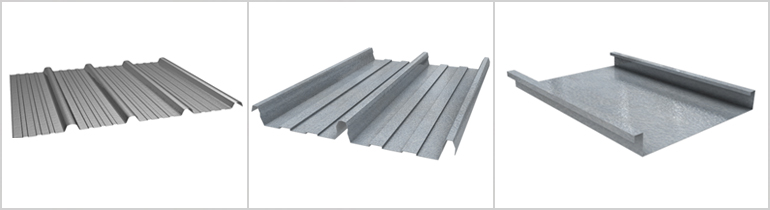

Interarch Tracdek Engineered Metal roof and wall cladding profiles have been the preferred systems for industrial Projects, warehousing, airports, commercial buildings, and residential buildings, for the last 20 years. Interarch has installed over 5 million square meters of its systems and offers the Tracdek system in just 3 Roof profiles and 2 wall systems.

The most commonly used, Tracdek Hi-Rib system is a pierced fixed roof and wall covering system, consists of structurally-engineered profiled panels that are available in single length and are fixed by means of self-drilling fasteners.

The TRACDEK Klippon system is a concealed fixed snap-on seam roof/wall covering system that consists of structurally strong high-ribbed panels. Long lengths and weatherproof side lap allow the Klippon® profile to be safely installed in commercial, educational, institutional, domestic and recreational buildings.

The TRACDEK® SS-2000 system also known as a Structural Standing Seam Roof System is a completely concealed fastener system with ability to have limitless single length panels spanning from the ride of the building to the eaves. It allows on site roll forming and can accommodate a slope down to 1 is to 40.

Tracdek systems are engineered to provide an insulated roof and wall system that improves the quality of the environment inside the building regardless of the external geographic location, environment, and weather.

|

| Green Building Week |

| |

|

| GBCs and their member companies including IGBC in India and around the world celebrated World Green Building Week from 16 to 20 September 2013. |

|

|

| Benefits of Green Buildings |

|

|

|

30-40% reduction in energy consumption |

|

20-30% potable water savings |

|

Increased green cover |

|

Daylight and view for occupants |

|

Enhances indoor air quality |

|

Provides healthier spaces |

| Growth of Green Buildings in India |

|

2100 plus registered green building projects |

|

1.64 billion Sq. ft of green building footprint |

|

19,000 plus trained green building professional |

|

400 plus IGBC certified & functional green building |

|

|

|

| Sector Spotlight - Rice Industry |

| |

|

India is one of the world's largest producers of white rice and brown rice, accounting for 20% of all world rice production. Rice is India's preeminent crop, and is the staple food of the people of the eastern and southern parts of the country. Rice is one of the chief grains of India. Moreover, our country has the biggest area under rice cultivation, as it is one of the principal food crops. India is one of the leading producers of this crop. Hassad Food Co., the agricultural investment arm of Qatar’s sovereign wealth fund, will invest up to $500 million in India says a recent report.

On current reckoning, given the second highest level of production in 2012-13, large public stocks, liberal export policy and weak currency, there is a great opportunity for Indian to retain its top rank as rice exporter in 2013.

The FAO has forecast that in 2013, Indian export will be 8.3 MT out of the

total world trade of 37.4 MT. Onset and progress of the southwest monsoon during June-September period will have to be tracked closely for production prospects in 2013-14. Given that general elections will be held early 2014, any strident price escalation in the domestic market for whatever reason

may prompt a reconsideration of the liberal export policy.

Interarch structural steel solutions for Rice Industry

| Milling Unit |

Boiler Room |

| Processing Unit |

Cooling Unit |

| Storage Unit |

Admin Block |

| Packaging Unit |

Staff Rooms |

|

|

|

| Customer Testimony |

| |

|

It gives us immense pleasure to certify that Interarch project team has done a commendable job on It gives us immense pleasure to certify that Interarch project team has done a commendable job on

our project. Interarch team has achieved lowest rework percentage of project.

The cooperation, diligence & dedication demonstrated by your team have been noticed. We would like

to thank Interarch for their significant contribution to our division’s success & we look forward to do business with you again in future

|

| Project Management Tip - Safety in Roof & Wall System Installation |

| |

|

|

|

|

Safe access must be provided to the roof always. The most common method used for accessing the roof is by using scaffold which is specifically installed for this purpose or by MEWP |

|

Before installing the Tracdek roof sheet, safety net should be installed properly |

|

Full body safety harnesses should have adequate anchorage points / lifelines and ensure they are properly used through appropriate discipline, training and supervision |

|

Do not allow more than 3 workers latch to a single lifeline |

|

Tracdek Roof sheet must be lifted on to the roof by crane or manually by workers |

|

The spreader beam must be used for lifting the Tracdek roof sheets by crane |

|

Manually Tracdek roof sheets will be pulled one after the other on to the roof and should be placed to the right position by workers wearing proper PPE like full body safety harness connected to static life lines, safety gloves etc. |

|

Do not handle or try to fix Tracdek roof sheet materials during windy conditions |

|

Tracdek Roof sheets lifted on to the roof will be arranged to adjacent bays, pilled and tied safely to purlins before installation |

|

The hand tools, nuts, bolts should always be carried in tool bags |

|

Tracdek Roof sheet must be installed one by one manually |

|

The persons working on the Tracdek roof sheets should never disconnect the hooks of their full body safety harness from the lifeline |

|

The worker should not push the dissected Tracdek roof sheet with his foot for creating the DLP / Turbovent opening |

|

The movement of man / material under the work area of the DLP / Turbovent opening should be ceased |

|

While walking on the Tracdek roof sheet do not step on a panel major rib and do not walk on any panel that has not been properly secured to the structure |

|

Workers must be warned in advance about the openings on to the roof |

|

Platform for cladding work must be flat and strong and the worker should use the required PPE's like full body safety harness, safety helmets, safety gloves etc. |

|

|

|

|

| Building Made Possible in Steel |

| |

|

| Building Name |

U. S. Steel Tower, Pittsburg, USA |

| Tonnage: |

40, 000 MT of steel |

| Floor Area |

2.1 Lacks Sq. M |

| Floors: |

64 |

| Height: |

256 M |

| Building Usage |

Commercial office |

|

|

U. S. Steel Tower, Pittsburg, USA is also known as the Steel Building (formerly USX Tower).

It is the tallest skyscraper in Pittsburg and the 37thtallest in United States. The 64-story tower was finished in 1970 and is 256 meters (841 feet) high.

The main frame is made out of steel, also displayed on the exterior of the building throughout huge Corten steel columns that resist the corrosive effects of all the weather conditions. On clear days, it is possible to spot the U.S. Steel Tower from as far as 50 miles (80 km) away. The building also made history by being the first to use liquid-filled fireproofed columns. |

|

| |

| New Project Wins |

| |

|

Lafarge India Ltd., Chhattisgarh |

|

|

Ultratech Cement Ltd., Chhattisgarh |

|

Suprint Textile Pvt. Ltd., Rajasthan |

|

Udaipur Beverages Ltd., Madhya Pradesh |

|

Parijat Industries Ltd., Haryana |

|

| |

| Press Coverage |

| |

|

Steel & Metallurgy |

|

|

Steel Structures & Metal Buildings |

|

| |

| Projects Completed |

| |

|

DB Corp Ltd., Rajasthan |

|

|

R & B Denims Ltd., Gujarat |

|

Tata Motors Ltd., Uttrakhand |

|

Nila Sea Foods Pvt. Ltd., Tamil Nadu |

|

Prestress Wire Industries, Uttrakhand |

|

| |

| Events |

| |

|

Interarch conducted its 6th Annual Project Meet 2013 on 24 Sep’2013. |

|

|

| |

|

Interarch conducted Building Innovators Seminar in Kolkatta on 6 September 2013 to showcase Urban Infrastructure Projects in Steel Structures & Pre-Engineered Steel Construction. |

|

|

| |

|

|

|

|

|

|

Click here to submit your enquiry online |

|

| INTERARCH BUILDING PRODUCTS PVT. LTD.

Central Marketing Office, B-30, Sector 57, Noida - 201 301, India

Tel.: +91-120-4170200, 2581029 | Fax: +91-120-2581017 | E-mail: info@interarchbuildings.com |

visit us at: www.interarchbuildings.com, www.interarchinfra.com |

|

|

Over the years, Interarch has successfully achieved a benchmark in providing best Project Management System in the industry for effective execution of projects within the desired timelines. The company has in place, an exhaus-

Over the years, Interarch has successfully achieved a benchmark in providing best Project Management System in the industry for effective execution of projects within the desired timelines. The company has in place, an exhaus- The Indian Pre-Engineered Steel Buildings (PEB) market is experiencing robust growth fuelled by infrastructure development and the increasing popularity of PEB systems in the industrial sector. It has been an interesting journey for the PEB industry over the last almost three decades in terms of observing the changing trends in the Indian construction industry. There have been times when pre-engineered solutions were not much in demand, but, gradually with the due course of time, people are becoming more aware and inclined towards it.

The Indian Pre-Engineered Steel Buildings (PEB) market is experiencing robust growth fuelled by infrastructure development and the increasing popularity of PEB systems in the industrial sector. It has been an interesting journey for the PEB industry over the last almost three decades in terms of observing the changing trends in the Indian construction industry. There have been times when pre-engineered solutions were not much in demand, but, gradually with the due course of time, people are becoming more aware and inclined towards it.

It gives us immense pleasure to certify that Interarch project team has done a commendable job on

It gives us immense pleasure to certify that Interarch project team has done a commendable job on