|

|

| |

|

| |

|

|

| Possibility of Interarch Pre-Engineered Steel Buildings for Schools & Colleges |

|

| |

|

| School & college buildings construction faces a great challenge in today's cities due to time and space constraint. School buildings must withstand a considerable amount of wear and tear on a daily basis and be functional for many years. Interarch pre-Engineered Steel Buildings are ideal for School and Colleges |

|

| Benefits of Interarch steel framing for Educational Buildings: |

|

Flexibility in construction and aesthetic look |

|

Large grid span as per class room requirement |

|

Low lifetime maintenance cost and durability |

|

Easily expandable for growing need with the time |

|

Faster construction resulting early occupancy |

|

| Applications possible for schools & Colleges: |

|

School or College Buildings |

|

Auditoriums & Halls |

|

Indoor & Outdoor Stadiums |

|

Administrative Buildings |

|

Lecture Theatres |

|

Classrooms and Laboratories |

|

Training Centre |

|

Hostel Blocks |

|

Library Building |

|

Cafeteria |

|

|

|

| |

|

|

| Project Spotlight: G+ 2 Hostels Building for Thapar University |

|

| |

|

Interarch engineered, manufactured & delivered Pre- Engineered Steel Multi-storey hostel building for Thapur University in Punjab. Thapar University, formerly known as Thapar Institute of Engineering and Technology, was founded in 1956 by Karam Chand Thapar and is situated in Patiala. Thapar University is today considered among the leading privately managed engineering institutions of the country.

Interarch constructed the new hostel block, spread over an area of 43,000 Sq. feet. It will provide accommodation to over 800 students of the university. |

|

| |

|

| |

| Project Name |

Thapar University |

| Project Location |

Patiala , Punjab |

| Building Usage |

Hostel Building |

| Project Area |

13000 Sq.M |

| No. of Buildings |

Building 1 |

Building 2 |

| Length |

111 M |

56 M |

| Width |

50 M |

54.4 M |

| Height |

13.45 M |

13.45 M |

| Design Code |

AISC-05(Allowable Stress Design) |

| Dead Load |

100 mm thick RCC+50 mm floor finish |

| Collateral Load on floors |

0.15 KN/m2 for false ceiling |

| Live Load |

0.57 Kn/m2 on roof , 3.5 Kn/m2 on floors, 10 KN/m2 on Gym area |

| Flooring |

Deck System and RCC Floor |

| Ceiling |

84C Metal Ceiling used in all the areas |

| Seismic Zone |

IV |

| Dry Wall |

LGFS |

| Roof Sheeting Profile |

Trackdek Hi-rib Roof Trackdek Hi-rib Roof |

|

| |

|

| |

|

|

| |

|

|

| Goals of Green Buildings: What is a Green Building? |

|

| |

|

The concept of sustainable development can be traced back to fifty years, the green building movement in the U.S. originated from the need and desire for more energy efficient and environmentally friendly construction practices. There are a number of motives for building green, including environmental, economic, and social benefits. The concept of sustainable development can be traced back to fifty years, the green building movement in the U.S. originated from the need and desire for more energy efficient and environmentally friendly construction practices. There are a number of motives for building green, including environmental, economic, and social benefits.

Green building brings together a vast array of practices, techniques, and skills to reduce and ultimately eliminate the impacts of buildings on the environment and human health. It often emphasizes taking advantage of renewable resources, e.g., using sunlight through passive solar, active solar, and using plants and trees through green roofs, rain gardens, and reduction of rainwater run-off. Many other techniques are used, such as using low-impact building materials or using packed gravel or permeable concrete instead of conventional concrete or asphalt to enhance replenishment of ground water.

On the aesthetic side of green architecture or sustainable design is the philosophy of designing a building that is in harmony with the natural features and resources surrounding the site. There are several key steps in designing sustainable buildings: specify 'green' building materials from local sources, reduce loads, optimize systems, and generate on-site renewable energy. |

|

|

|

|

| Customer Testimonial |

|

| |

|

Interarch Building Products executed Pre-Engineered Building project on our Manufacturing Unit at Soltex Petro Products Limited at Silvassa in Gujarat. We are satisfied with the work & happy with the timely completion of the project. Interarch Building Products executed Pre-Engineered Building project on our Manufacturing Unit at Soltex Petro Products Limited at Silvassa in Gujarat. We are satisfied with the work & happy with the timely completion of the project.

We wish Interarch very best in all their future endeavors. |

|

|

| |

|

|

|

| Project Management Tip: Tools required for sheeting installation |

|

| |

|

| There are tools which make the proper installation of the sheeting faster & easier. Interarch Certified Builders uses the following tools for installation of Sheets: |

| |

|

|

|

| Power Screw Driver Machines with TORQUE Adjustment and Depth Gauge |

|

|

| |

| Hex Head Socket for Hex Head |

Nibbler Machine. Self-Drilling Screws |

|

|

| |

| Scissor for Steel Sheet Cutting (R) |

Scissor for Steel Sheet Cutting(L) |

|

|

| |

| Rivet Machine |

Turn up and Turn Down Tool |

|

|

| |

| Plastic Hammer |

Spirit Level |

|

|

| |

|

|

| Project Completed |

Project Won |

|

|

|

|

|

|

|

Tata Motors Limited in Uttarakhand |

|

Satnam Motocorp Pvt Ltd in Rajasthan |

|

Astrotech Steel Pvt Ltd in Andhra Pradesh |

|

Geeta Industries in Uttarakhand |

|

Chandan Singhania in Odisha |

|

|

|

|

|

|

|

|

|

Tata Motors Limited in Gujarat |

|

Adani Enteprises Ltd in Madhya Pradesh |

|

IM Gears Pvt Ltd in Tamil Nadu |

|

Ultratech Cement Limited in Rajasthan |

|

SKH Landbase Pvt Ltd in Haryana |

|

|

|

|

| |

|

|

| Young Builder Program |

|

| |

|

Young Builder Program gives an insight about Pre-Engineered Buildings and educates Young Architects & Engineers about the Indian Pre-Engineered Steel Industry, various applications & nomenclature of Metal buildings.

Interarch conducted Young Builder at Pimpri Chinchwad College of Engineering at Pune in September’2016. The session was conducted by Mr. Sandeep Koul (AVP of Sales & Marketing). |

|

|

| |

|

|

|

| Event at Interarch |

|

| |

|

| Interarch organized Closed Group Interaction at Indian Habitat Centre in New Delhi on 9 September’16. |

|

|

| |

| |

|

|

|

| Celebration at Interarch: Vishwakarma Day |

|

| |

|

| Interarch celebrated Vishwakarma day at Tamil Nadu Unit on 17th September 2016. |

|

|

| |

|

|

|

| Building made possible in Steel: U.S. Steel Tower |

|

| |

|

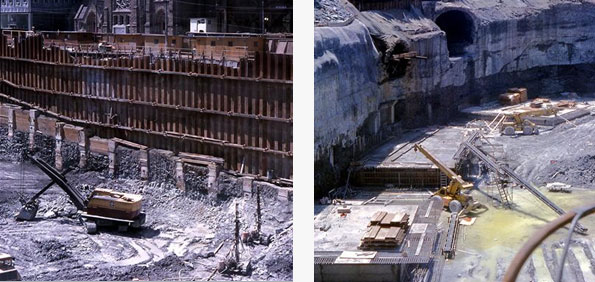

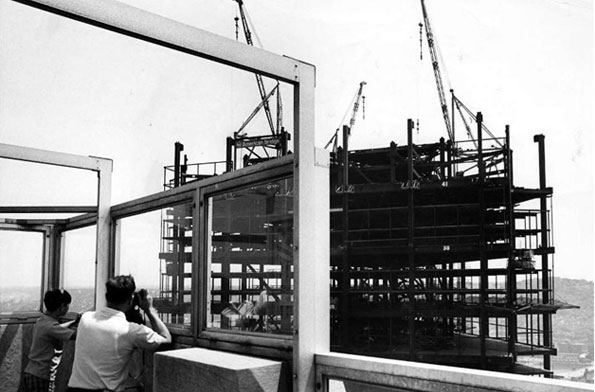

The United States Steel Corporation, one of the largest steel producers in the world, wanted to make a statement about the strength and beauty of steel. The original concept was to design the tallest building in the country, with an outer facing completely made of Cor-Ten Steel. It was to be a huge advertisement for the steel industry, which was centered in Pittsburgh.

The United States Steel Corporation, one of the largest steel producers in the world, wanted to make a statement about the strength and beauty of steel. The original concept was to design the tallest building in the country, with an outer facing completely made of Cor-Ten Steel. It was to be a huge advertisement for the steel industry, which was centered in Pittsburgh.

The U.S. Steel Tower is architecturally noted for its triangular shape with indented corners. The building also made history by being the first to use liquid-filled fireproofed columns. U.S. Steel deliberately placed the massive steel columns on the exterior of the building to showcase a new product called Cor-ten steel. Cor-ten resists the corrosive effects of rain, snow, ice, fog, and other meteorological conditions by forming a coating of dark brown oxidation over the metal, which inhibits deeper penetration and doesn't need painting and costly rust-prevention maintenance over the years for U.S. Steel Tower, also known as the Steel Building (formerly USX Tower) is a 64-story, 256.34 m (841.0 ft) skyscraper with 2,300,000 sq ft of space

Structural steel: 44,000 U.S. tons (40,000 metric tons)

Height: 256.3 M / 841 ft

Floors Above ground: 64

Floors below Ground: 3

|

| Construction work on the foundation |

|

|

|

| Building Rising in 1970. |

|

|

|

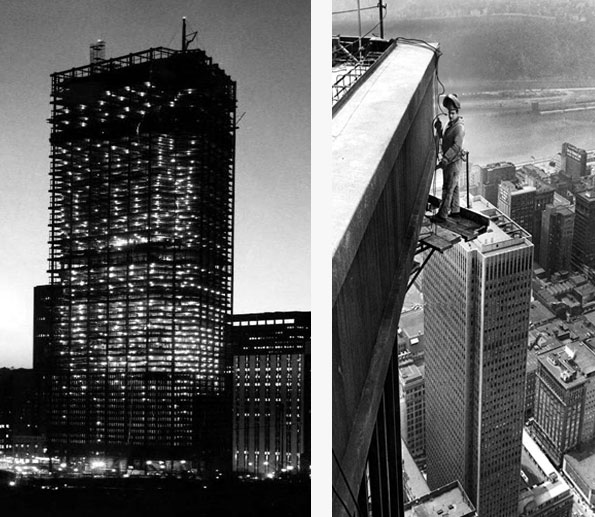

| The Steel Building in 1969 (left) and an ironworker standing on scaffolding near the top in 1970. |

|

|

|

|

|

| |

|

|