Mandatory documents to be maintained at site during project execution

- A copy of customer order received

- Copy of work order released to erector by Interarch

- Project Macro Schedule (in line with customer’s requirement) duly accepted by erector

- Erection Methodology duly approved by Interarch’s engineering department & Regional head/Team Leader

- Resource Plan duly approved by Interarch’s Regional Head/Team Leader

- Project specific safety plan duly approved by the Safety Manager to be maintained

- Anchor Bolt (AB), General Arrangement (GA), Erection, and Sheeting drawings stamped as “Good for construction /execution” to be present at site always

- Shipper’s list i.e., an itemized list of all materials to be used for the project

- Format of Daily Progress Report, Check lists and all QMS/ISO documents should always be maintained

- Name & contact numbers of all Key persons from projects

- Torque table, test certificates, calibration certificates & fitness certificates of all tools & tackles and of measuring instruments like calibrated torque wrench tape of length 5M, 15M & 100M, etc. and other moving equipment

- Copy of Workman Compensation Policy, Labor License, & Contractor All Risk (CAR) policy (if required)

Check list before starting the erection

- Always check, center to center distance of girds and bays with reference to AB and diagonal distance of each grid / bays references

- Shipper list quantity to be cross checked with erection drawings

- All tool &tackles required for the erection process must be cross checked with erection drawings and to be available at site before starting the work

- Before commencement of erection a hand over report from civil contractor or consultant must be procured

- Foundation stability certificate to be submitted which should be duly signed by the structural engineer

- Ensure that all the material required for completion of a bay is available at site at its respective location on the previous day

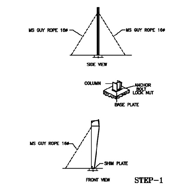

Column Erection

- Column is arranged with all fixtures & painting duly Completed

- Lifting sling is fixed to the column at exact position of lift

- Guy ropes are fixed to the column before lifting

- Lifting equipment lifts the structural column vertically and is positioned in the Pedestal

- Anchor bolts nuts should be fixed and tightened

- Guy ropes are tied as shown in the figure

- Column plumb is checked and sling is released using Boom lift or Scissor lift

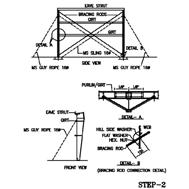

Braced Column Erection

- Same Procedure is followed for lifting the second column

- The Portal beam is the primary tying member between the two columns. It is lifted using Crane and boom lift used for bolting the portal beam.

- The Eave Strut is immediately erected after the erection of second Column.

- Bracing Rods should be lifted and fixed to the adjacent Columns. Hill Side washers are used to tighten the brace rods.

- The same procedure is followed for erection of the columns on the other side of the grid